| Availability: | |

|---|---|

| Quantity: | |

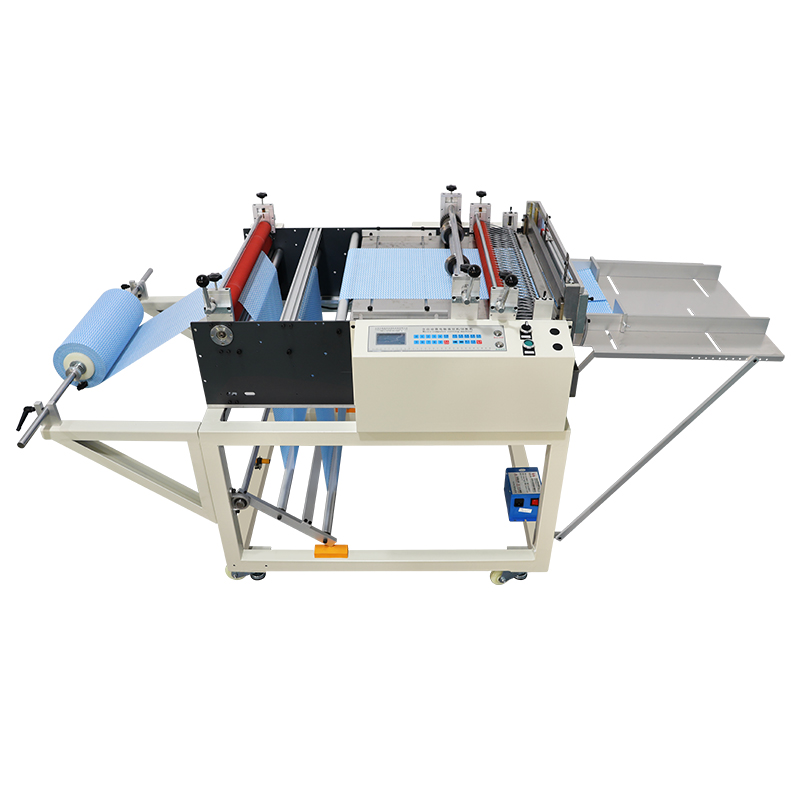

HDK-300ZC

HDK

The HDK - 500ZC Punching Cutting Sheet Machine by HDK is a state - of - the - art device that has redefined the standards of material processing. It brings together advanced technology, high - performance capabilities, and user - centric design.

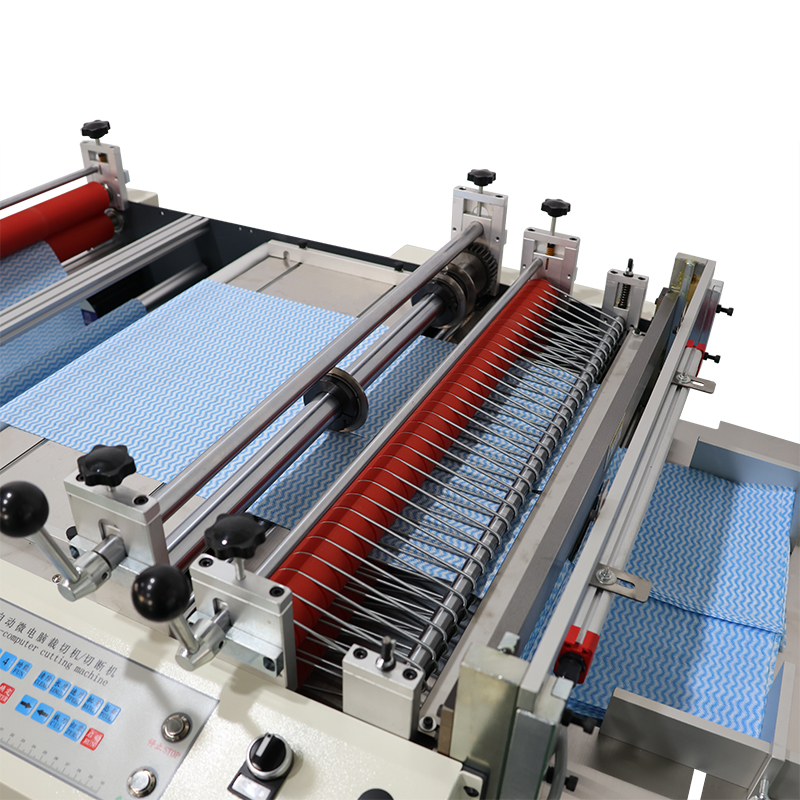

The precision of the HDK - 500ZC is truly remarkable. The combination of a feeding width of 500mm and a cutting precision of ±0.1mm ensures that every cut is exact. This level of accuracy is crucial, especially when working with materials where even the slightest error can lead to product failure. The adjustable cutting length provides the flexibility to create sheets of various sizes, from small - scale components to large - format products.

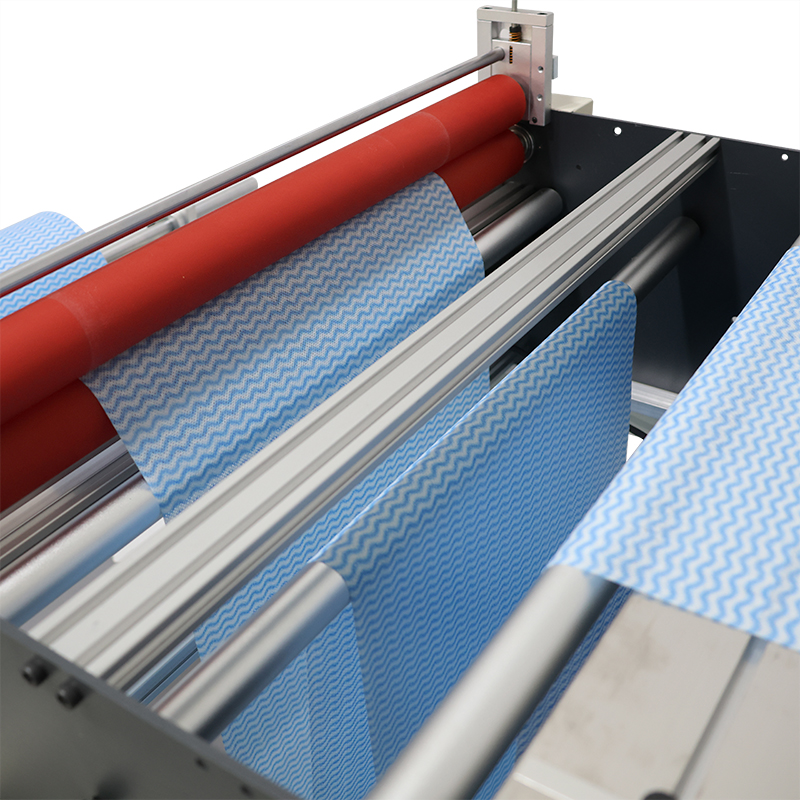

The cutting speed of 30 - 40 meters/min, with the potential to reach 80m per minute on high - speed settings, significantly increases production efficiency. The scissor - like motion of the sharp steel cutting knife not only cuts through materials quickly but also results in clean edges, eliminating the need for additional finishing processes in many cases.

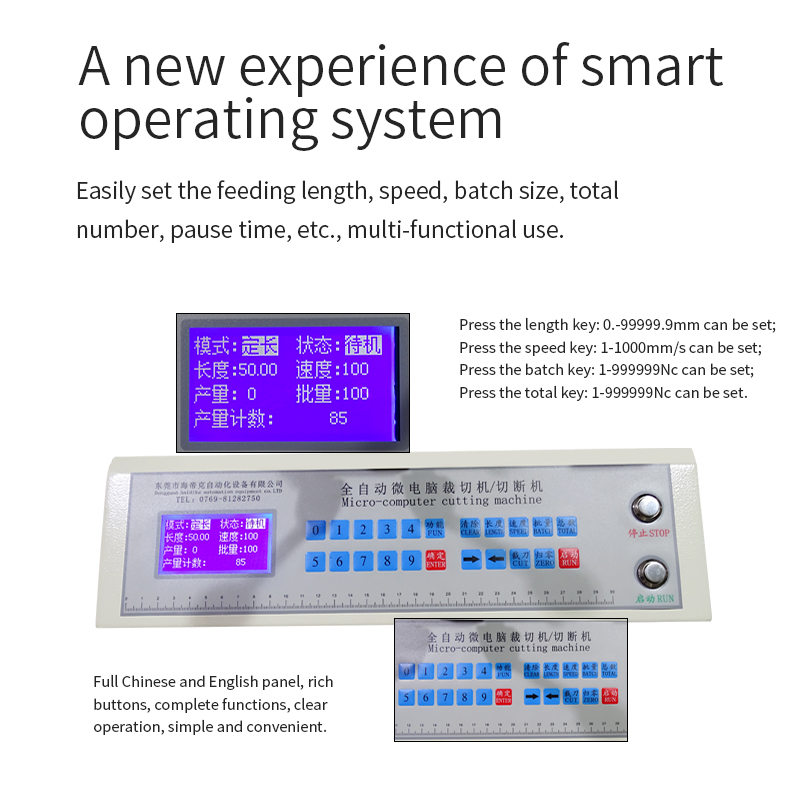

The PLD control system is the brain of the machine. It allows operators to easily set parameters such as feeding length, speed, batch size, and total number. The counter feature helps in monitoring and controlling the production process, ensuring that the desired quantity of sheets is produced accurately. The full Chinese and English panel, along with its simple operation, makes it accessible to a wide range of users, including those in international markets.

This machine's versatility in handling different materials is a major advantage. It can process paper - based products, plastic films, foam materials, metal foils, and composite materials. In the packaging industry, it can cut and punch various materials to create boxes, labels, and inserts. In the electronics industry, it can handle thin films and metal foils for circuit board manufacturing. In the automotive industry, it can process materials for interior and exterior components. Its wide - ranging material compatibility makes it an essential tool for any industry that requires precise material cutting and punching.

How do I maintain a roll-to-sheet cutting machine?