| Availability: | |

|---|---|

| Quantity: | |

HDK-1000ZC

HDK

Industrial Punching Cutting Machine For Paper, Plastic Film, Non-woven fabric

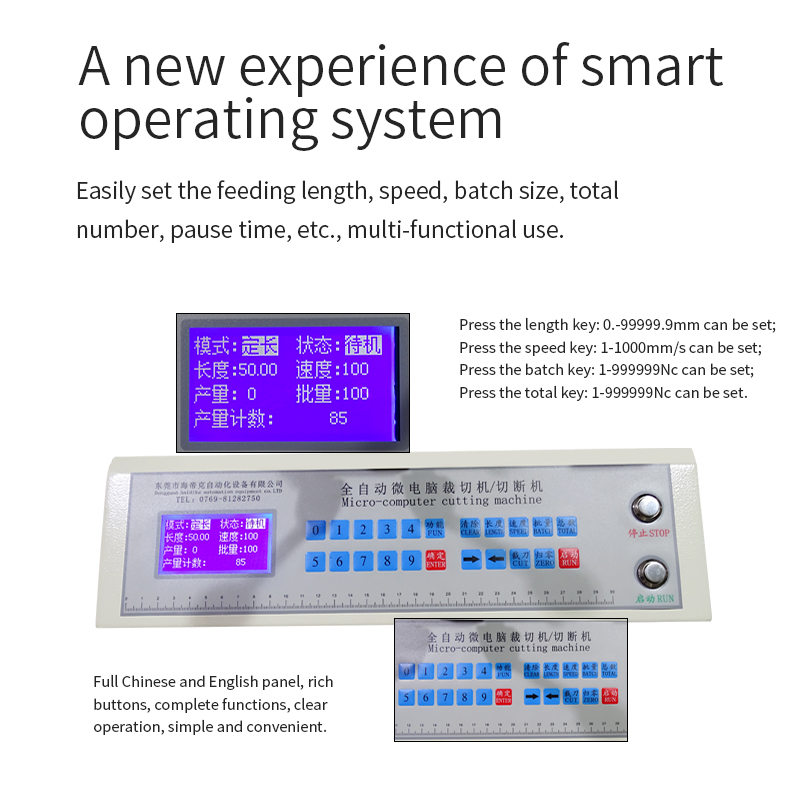

A roll-to-sheet punching cutting machine is a specialized piece of equipment used in manufacturing processes where a large roll of material (like paper, film, or foil) is fed into the machine, and it is then precisely cut into smaller sheets. The machine is typically used in industries like packaging, printing, and flexible material production, where there is a need to convert large rolls into smaller, standardized sheets.

Here’s how it works in general:

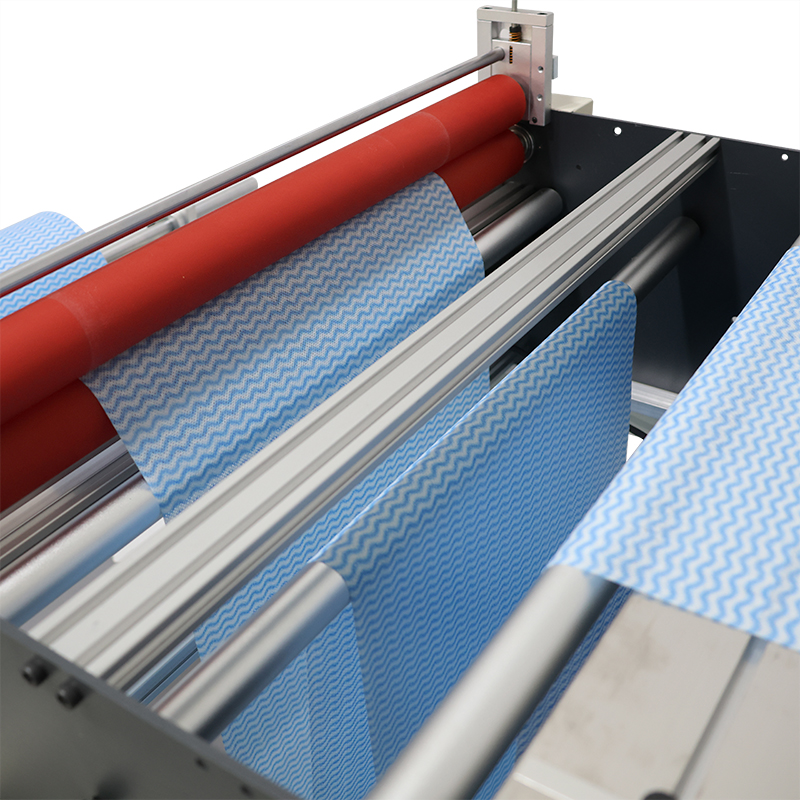

Feeding the Roll: The material roll is mounted onto the machine and unwound as it moves through the system.

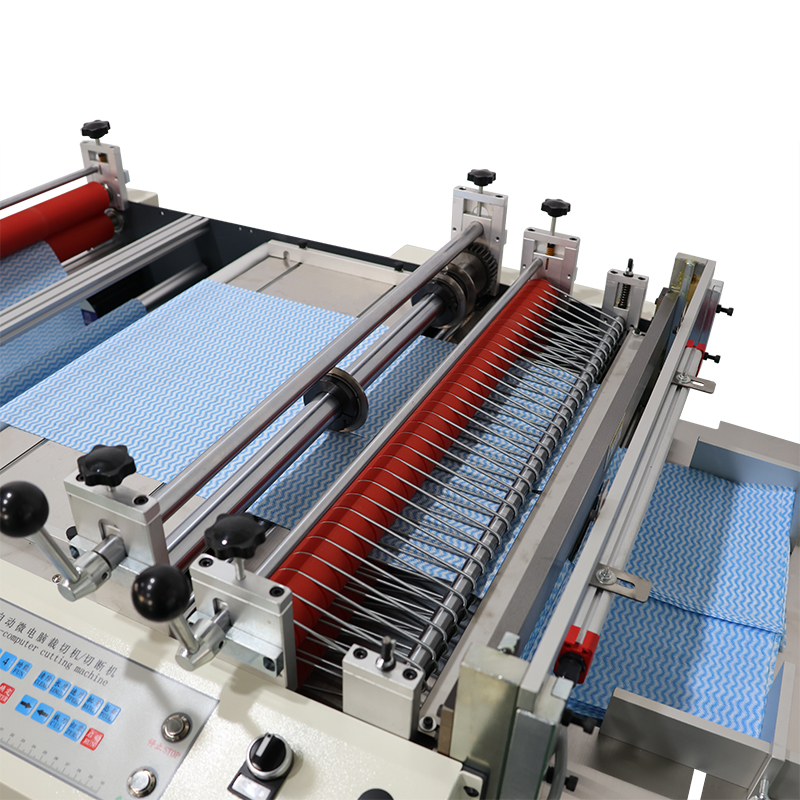

Punching and Cutting: The machine uses a combination of punching dies and cutting blades to perforate and then cut the material into the desired sheet size.

Sheet Collection: After cutting, the individual sheets are collected and stacked for further processing or packaging.

Using a punching machine in curtain manufacturing—especially for door curtains, window curtains, or mosquito nets—offers several key benefits:

Accurately punches holes for hooks, rings, or rods, ensuring a neat, professional appearance and consistent spacing.

Replaces manual hole-making with automatic or pneumatic punching, significantly speeding up production and reducing labor costs.

Allows customizable punching layouts for different curtain designs (e.g., single row, multiple rows, grommet spacing).

Delivers uniform hole size and placement, which is especially important for aesthetic products like curtains.

Handles materials like nonwoven fabric, mesh, plastic film, PEVA, or PVC, which are common in decorative and functional curtains.

Can be integrated with roll-to-sheet cutters to punch and cut in one process, saving space and improving workflow.

Accurate positioning reduces misaligned holes, minimizing rework and material waste.

How do I maintain a roll-to-sheet cutting machine?