| Availability: | |

|---|---|

| Quantity: | |

HDK-1300Z-FQ

HDK

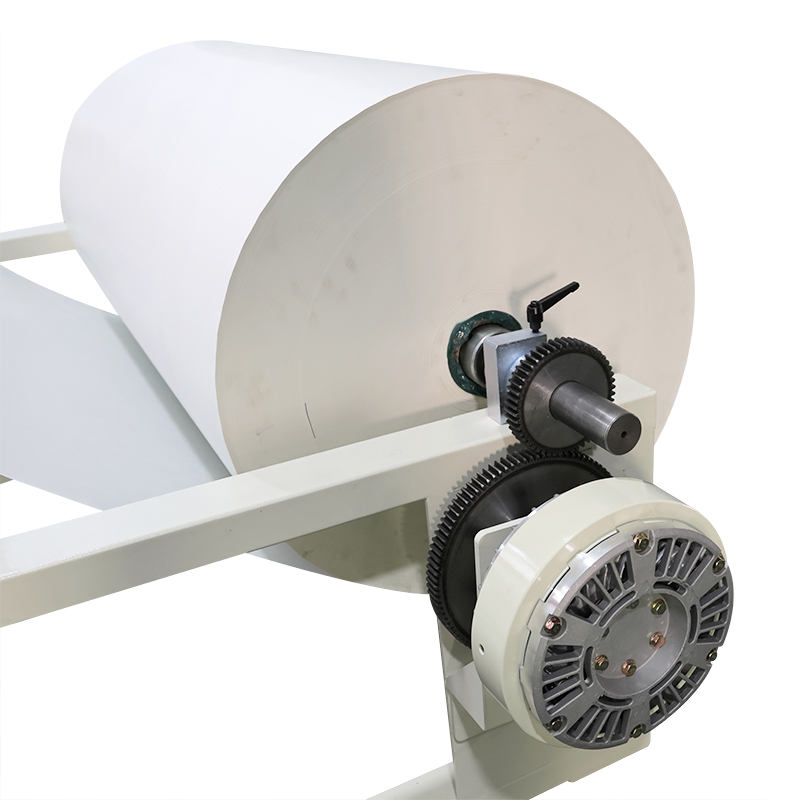

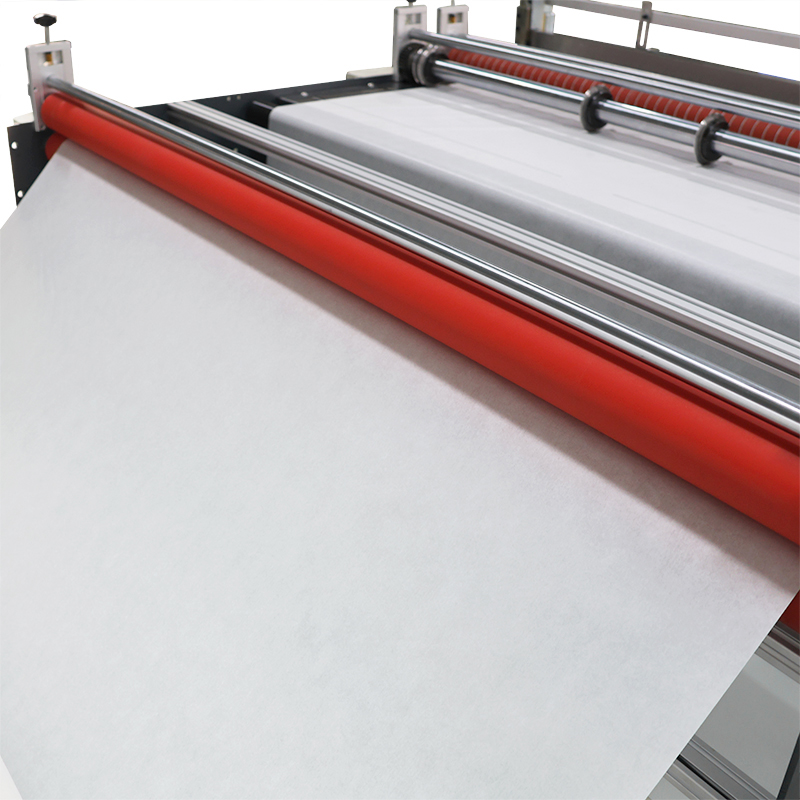

The Roll To Sheet Cutting Machine is a highly sophisticated piece of industrial equipment that combines mechanical precision, advanced automation, and intelligent control systems. The material feeding system is not only designed to handle a wide variety of rolled materials but also to ensure a consistent and stable supply during the cutting process. It features a variable speed control mechanism that can be adjusted according to the thickness and characteristics of the material being processed.

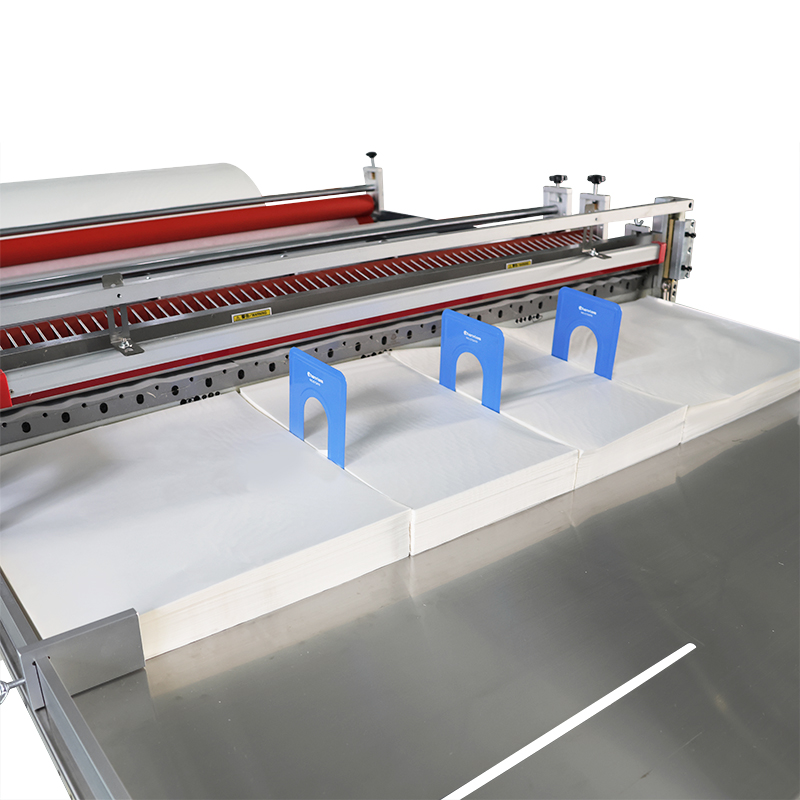

The cutting blade is made from a special alloy that offers exceptional durability and sharpness. It undergoes a rigorous heat treatment and grinding process to ensure a long lifespan and consistent cutting performance. The blade is also designed with a unique cutting edge geometry that minimizes friction and heat generation during the cutting process, resulting in cleaner cuts and less material waste.

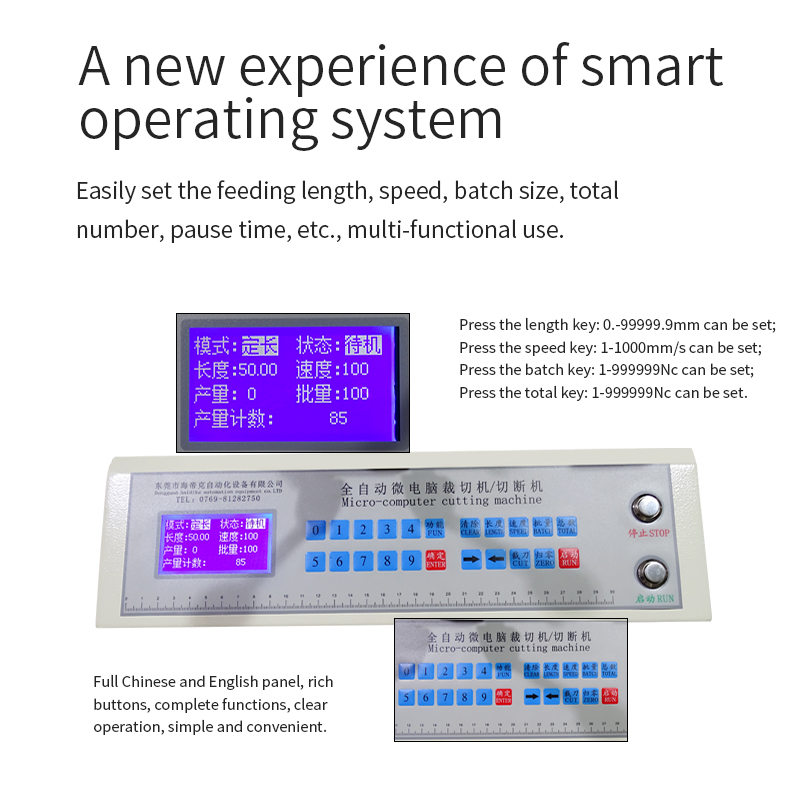

The machine's control panel is equipped with a high-resolution touchscreen display that provides intuitive access to all the machine's functions and settings. Operators can easily program cutting parameters, such as cutting length, speed, and blade position, with just a few taps on the screen. The control system also offers real-time monitoring of the cutting process, allowing operators to make adjustments as needed to ensure optimal performance.

1. Automatic Material Tension Compensation: To ensure accurate cutting, the Roll To Sheet Cutting Machine is equipped with an automatic material tension compensation system. This system continuously monitors the tension of the rolled material and adjusts the feeding speed and tensioning devices accordingly. This helps to prevent the material from stretching or wrinkling during the cutting process, resulting in more precise and consistent cuts.

2. Blade Wear Monitoring System: The blade is a critical component of the machine, and its condition directly affects the quality of the cuts. Our machine is equipped with a blade wear monitoring system that uses sensors to detect the wear of the blade over time. When the blade reaches a certain level of wear, the system alerts the operator, allowing for timely blade replacement and ensuring consistent cutting quality.

3. Data Logging and Analytics: The machine's control system has the ability to log and store data related to the cutting process, such as cutting speed, blade life, material consumption, and production output. This data can be analyzed to identify trends, optimize the cutting process, and improve overall production efficiency. For example, by analyzing the data, operators can determine the optimal cutting parameters for different materials, reducing production time and costs.

1. 3D Printing Material Preparation: In the 3D printing industry, our Roll To Sheet Cutting Machine is used to cut sheets of materials such as plastic, carbon fiber, and metal into the required sizes for 3D printing. The precise cutting capabilities of the machine ensure that the materials are cut to the exact dimensions needed, reducing waste and improving the quality of the 3D printed objects.

2. Composite Material Lamination: For industries that deal with composite materials, such as the aerospace and marine industries, our machine is used to cut composite sheets into the required sizes for lamination. The ability to cut composite materials with high precision and minimal damage to the fibers is crucial for ensuring the strength and performance of the final composite products.

3. Flexible Electronics Manufacturing: In the flexible electronics industry, where materials such as flexible printed circuits and organic light-emitting diodes (OLEDs) are used, our Roll To Sheet Cutting Machine is used to cut these delicate materials into the required shapes and sizes. The gentle cutting action and precise control of the machine ensure that the materials are not damaged during the cutting process, maintaining the integrity of the electronic components.

How do I maintain a roll-to-sheet cutting machine?