| Availability: | |

|---|---|

| Quantity: | |

HDK-500ZC

HDK

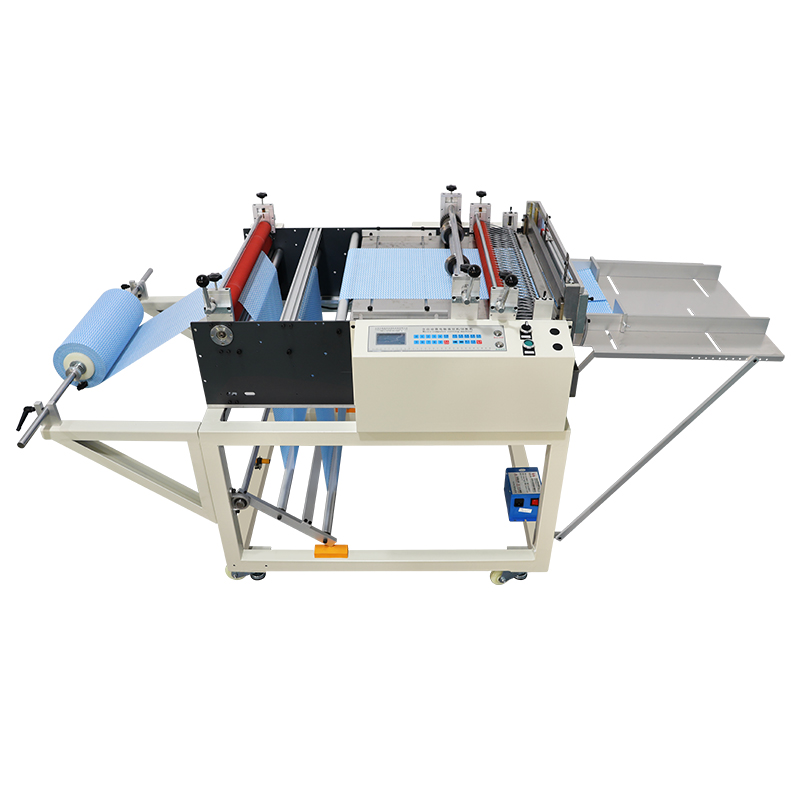

The Punching Cutting Sheet Machine, specifically the HDK - 500ZC model by HDK, is a revolutionary piece of equipment in the material processing industry. It's designed to meet the most demanding requirements of various sectors, offering a seamless combination of precision, efficiency, and versatility.

This machine's feeding width of 500mm allows it to process a significant amount of material in one go. The adjustable cutting length, ranging from 0.1 - 99999.9mm, provides flexibility that caters to a wide array of production needs. Whether it's for creating small, intricate parts or large - scale components, the HDK - 500ZC ensures accuracy with a cutting precision of ±0.1mm. The cutting speed, which can reach up to 40 meters/min, boosts productivity without compromising on the quality of the cut.

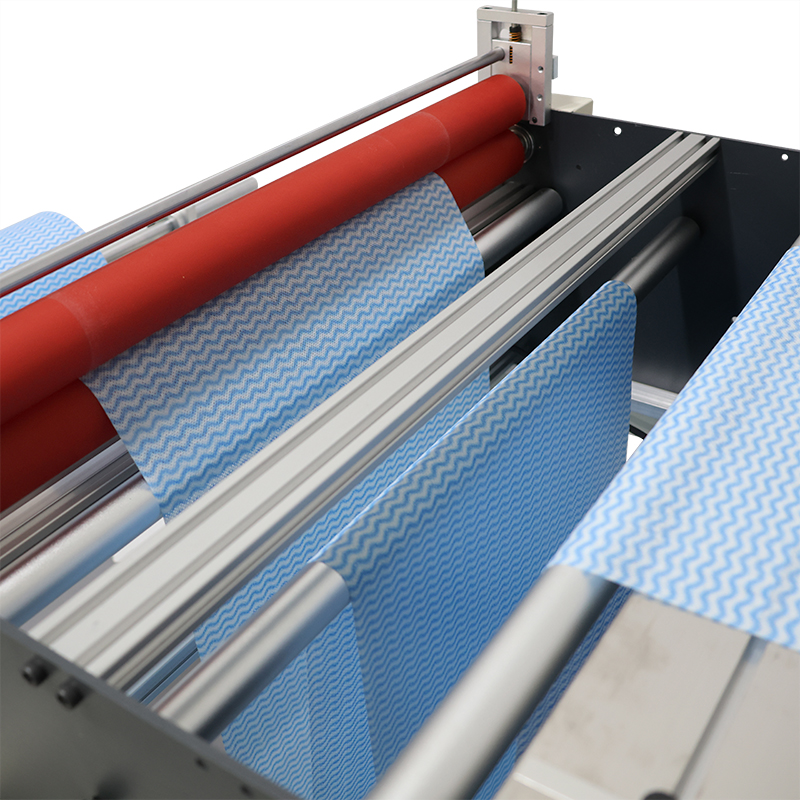

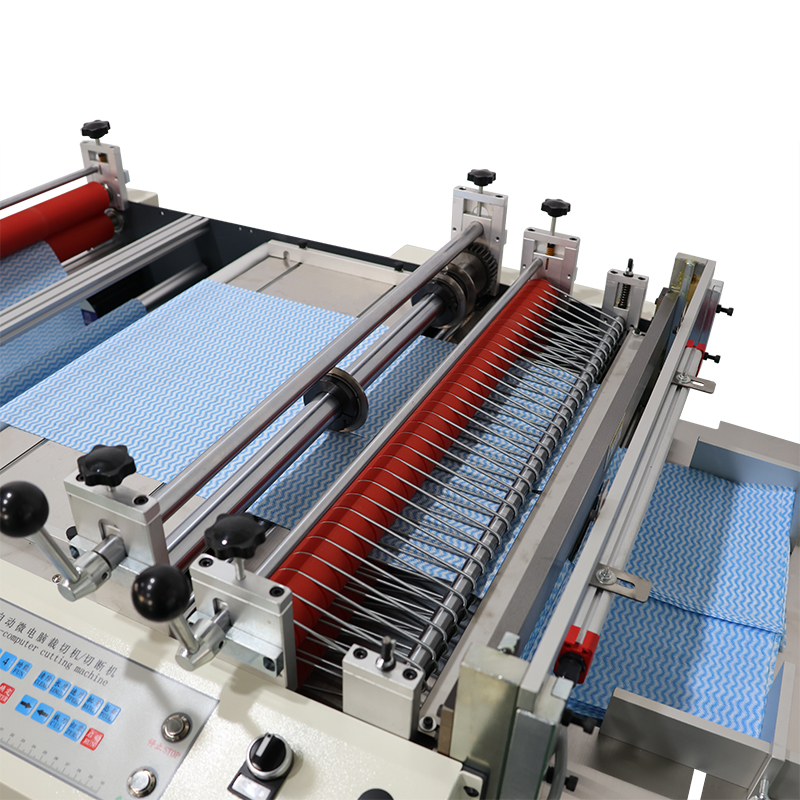

The punching and cutting mechanism is a standout feature. The cutting knife, crafted from sharp steel, uses a scissor - like up - and - down motion. This not only enables quick and efficient cutting but also guarantees clean, burr - free edges. On high - speed operations, it can achieve speeds of up to 80m per minute, making it ideal for high - volume production environments.

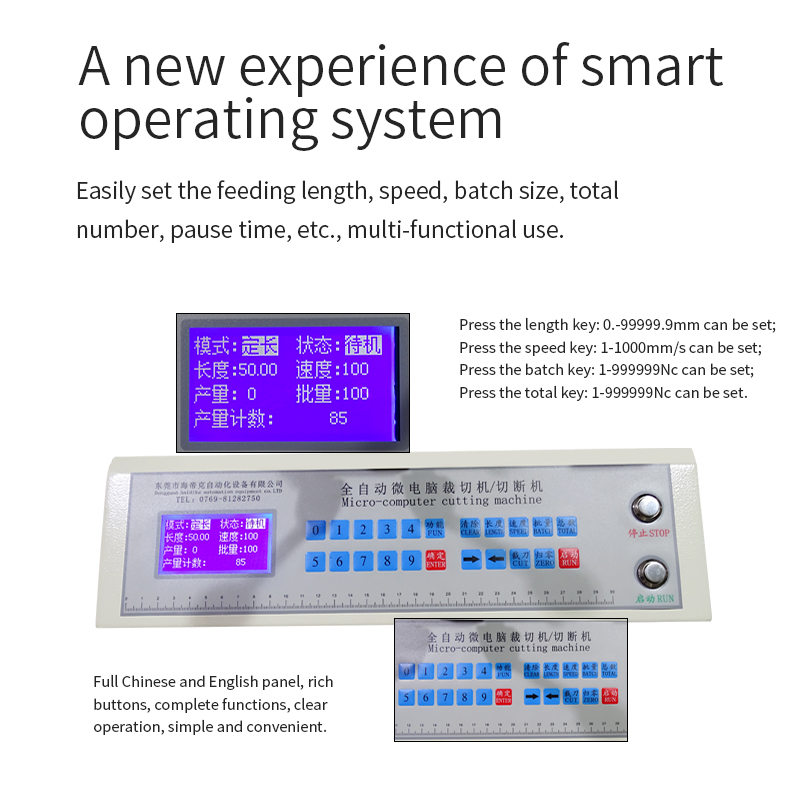

The control system of the Punching Cutting Sheet Machine is both user - friendly and highly adaptable. The PLD control system allows for precise adjustment of cutting length, speed, and batch quantity. It comes with a counter that helps in setting and tracking the desired cutting quantity, ensuring efficient production. The full Chinese and English panel, with its rich buttons and complete functions, makes operation clear and straightforward. Moreover, additional language customizations can be provided based on customer needs, making it suitable for a global market.

One of the machine's greatest strengths is its ability to handle a diverse range of materials. It can process paper materials such as coated paper, kraft paper, and self - adhesive paper with ease. In the realm of film materials, it's proficient in cutting PET, PVC, PP, and other plastic films. Foam materials like EVA foam and double - sided adhesive tape are no match for its capabilities, nor are metal foils such as aluminum and copper foil. Additionally, it can handle composite materials like metallized films and release paper, making it an all - in - one solution for many industries.

How do I maintain a roll-to-sheet cutting machine?