| Availability: | |

|---|---|

| Quantity: | |

HDK-700ZF

HDK

Roll To Sheet Slitting Machine is an advanced model with enhanced features and capabilities. It is designed to meet the growing demands of modern industries for high-precision and high-efficiency slitting and cutting operations. This machine incorporates the latest technology and high-quality components to ensure reliable and long-lasting performance.

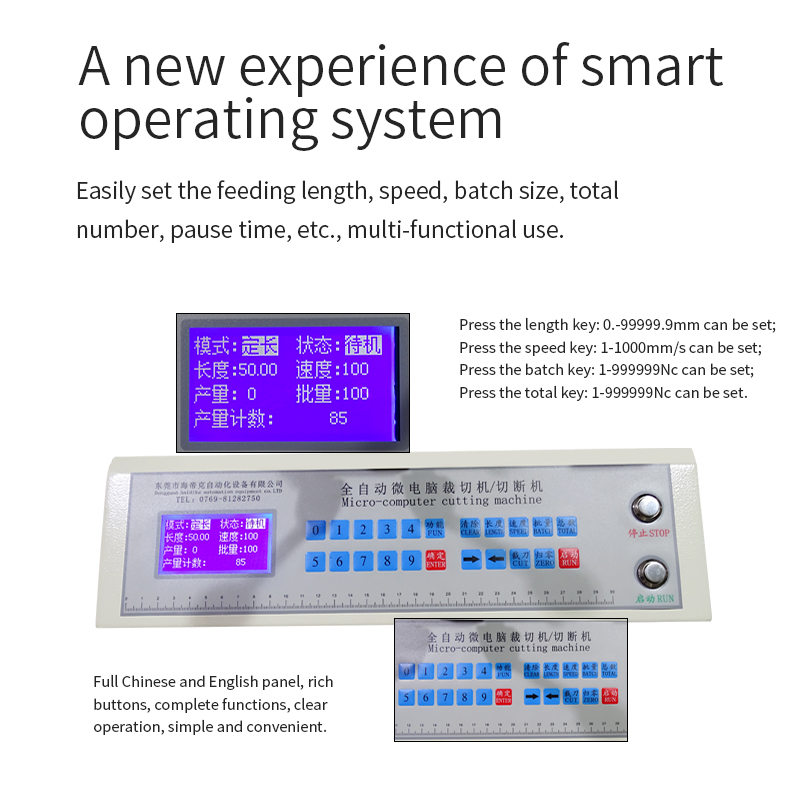

1. Intelligent Control System: Equipped with an intelligent control system that allows for easy programming and operation. It can store multiple slitting and cutting programs, enabling quick recall and setup for different production runs.

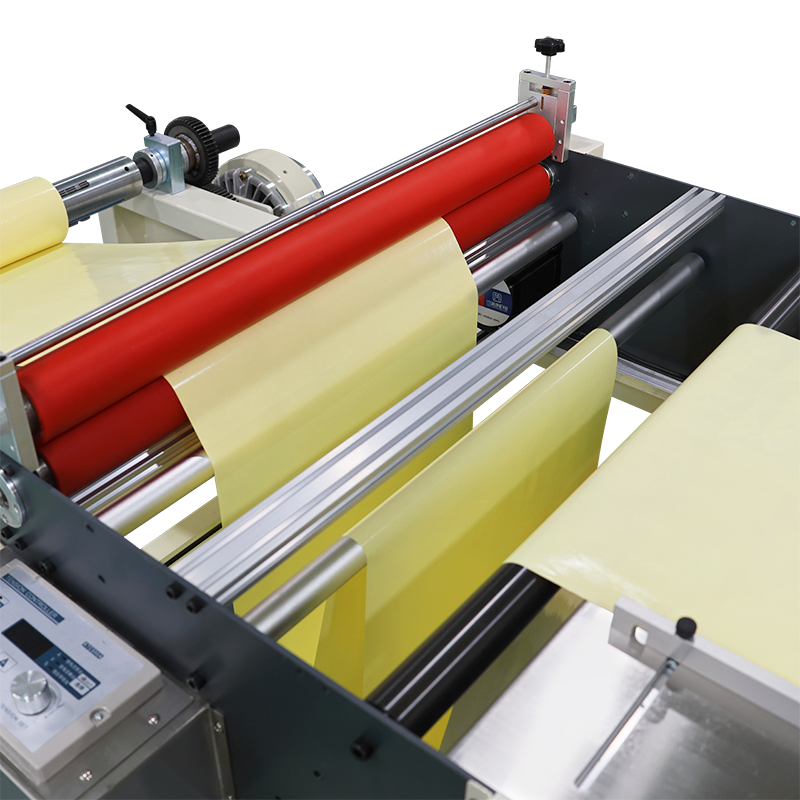

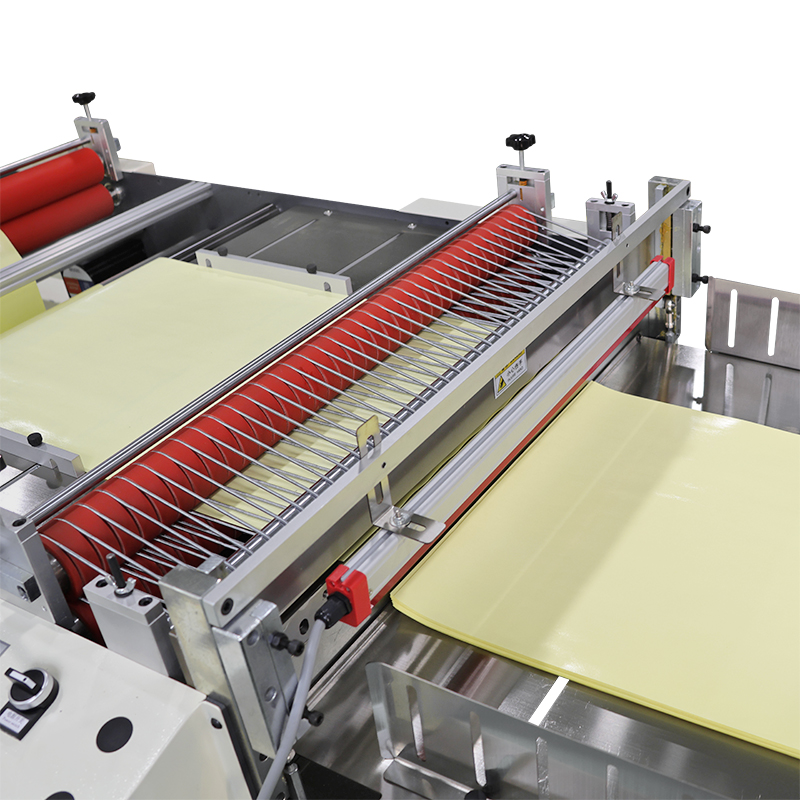

2. High-Quality Slitting Blades: The slitting blades are made of premium materials and have a longer lifespan. They are designed to provide sharp and clean cuts even on tough materials, ensuring the quality of the slitted strips.

3. Servo Motor Drive: Powered by a servo motor drive system, which provides accurate and stable power transmission. This results in more precise slitting and cutting operations, especially for materials that require high precision.

4. Online Monitoring and Adjustment: It has an online monitoring system that can detect any deviations in the slitting and cutting process in real-time. Operators can make adjustments immediately to ensure the quality of the products.

5. Dust Collection System: A built-in dust collection system helps to keep the working environment clean by collecting the dust and debris generated during the slitting and cutting process. This is especially important for materials that produce a lot of dust, such as paper and cardboard.

1. High-End Printing and Packaging: In high-end printing and packaging industries, this machine is used to slit and cut high-quality paper, cardboard, and plastic films for luxury packaging products. The precision and quality of the slitting and cutting operations are crucial for these premium products.

2. Electronics Manufacturing: For the electronics manufacturing industry, it can slit and cut metal foils, insulating materials, and flexible printed circuits with high precision. The intelligent control system ensures accurate dimensions for these sensitive electronic components.

3. Automotive Industry: In the automotive industry, it is used to slit and cut various materials such as fabric, leather, and plastic for automotive interior and exterior applications. The servo motor drive system provides the necessary precision for these applications.

4. Medical Device Packaging: This machine is suitable for slitting and cutting medical-grade packaging materials such as sterilization wraps and blister packaging films. The online monitoring and adjustment features ensure the quality and safety of the medical device packaging.

5. Aerospace Industry: In the aerospace industry, it can be used to slit and cut high-performance materials such as carbon fiber composites and metal alloys with high precision. The high-quality slitting blades and the intelligent control system make it suitable for these demanding applications.

How do I maintain a roll-to-sheet cutting machine?