| Availability: | |

|---|---|

| Quantity: | |

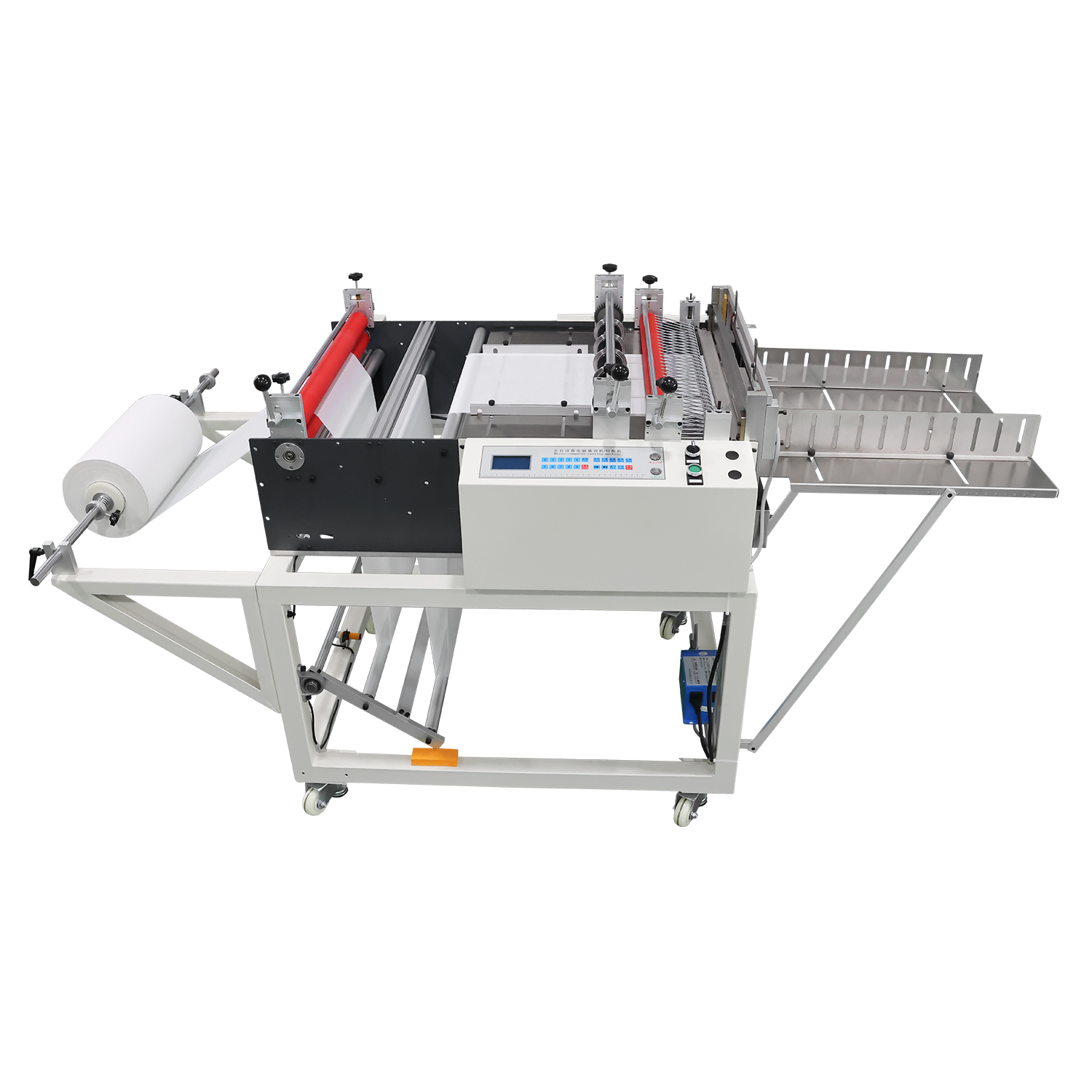

HDK-500ZC

HDK

Roll To Sheet Punching Machine And Cutting Machine

A punching cutting machine is designed to punch holes or shapes while simultaneously cutting materials from roll to sheet. It is especially useful in applications like nonwoven fabric, plastic film, paper, and packaging.

The non-woven roll to sheet punching machine is especially useful in the following sectors:

Medical and Hygiene Products: Face masks, disposable sheets, wet wipes, surgical dressings.

Agricultural Use: Non-woven seedling covers, crop protection sheets.

Packaging: Eco-friendly packaging inserts and liners.

Home Textiles: Pillow inserts, filters, curtains.

Industrial Uses: Insulation, filtration, automotive linings.

Key Features and Advantages

Integrated Punching and Cutting

Combines two processes into one, improving efficiency and saving labor.

High Precision and Consistency

Uses pneumatic or servo-driven punches to ensure accurate hole positions and uniform sheet lengths.

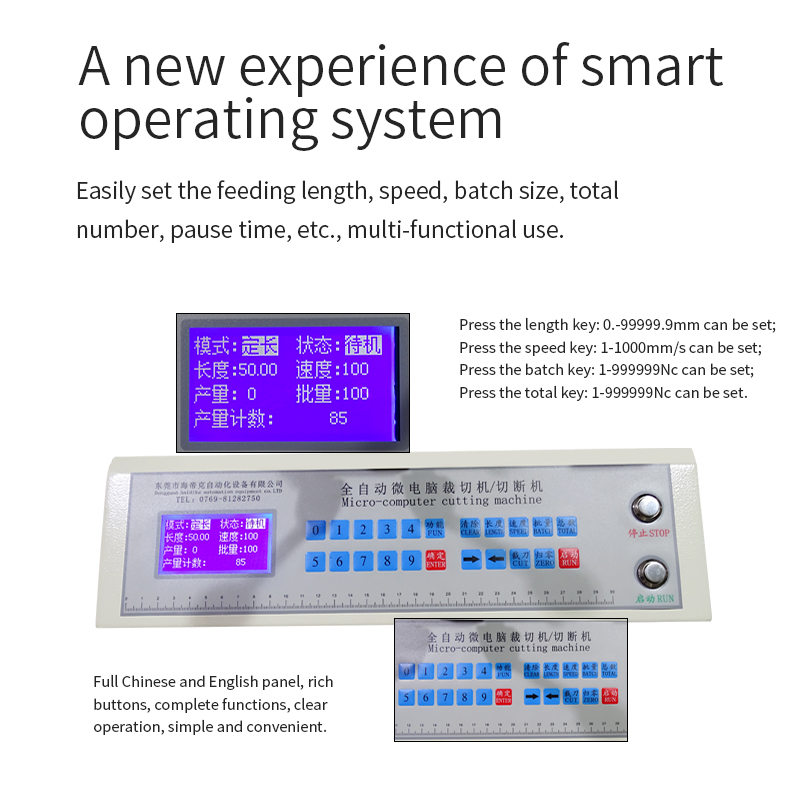

Fully Automatic Operation

Automatic feeding, punching, and cutting reduces manual workload and increases productivity.

Customizable Punching Patterns

Can be tailored to different hole shapes, sizes, and positions based on product needs.

Wide Material Compatibility

Suitable for nonwoven, plastic film, kraft paper, laminated materials, and more.

High Speed Performance

Capable of continuous operation at high speed, making it ideal for large-volume production.

Waste Reduction

Accurate punching and cutting minimize material waste and improve yield.

Can the punching pattern be customized?