| Availability: | |

|---|---|

| Quantity: | |

HDK-800ZF

HDK

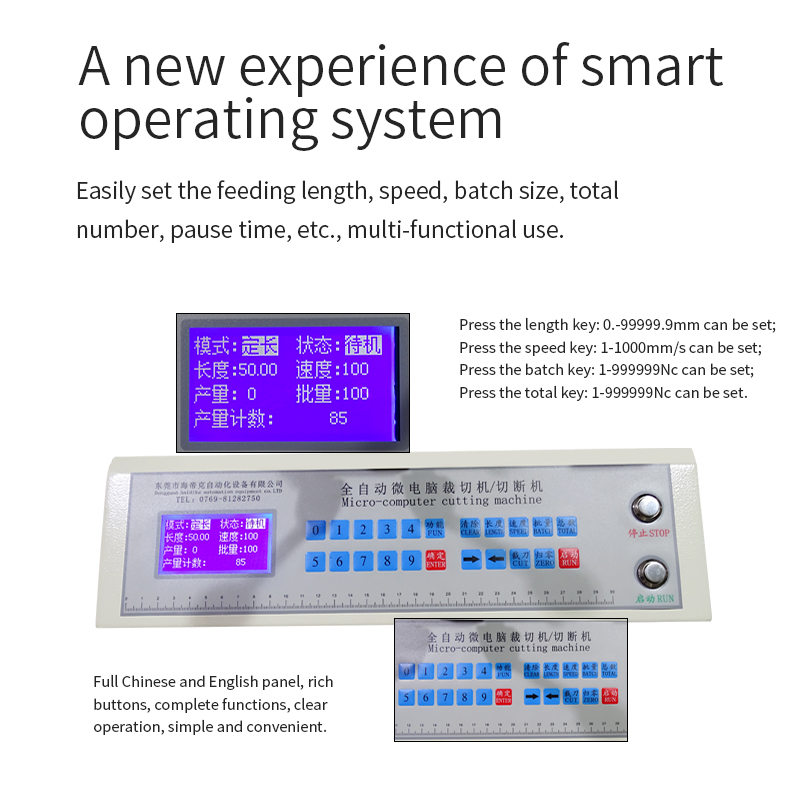

Roll to sheet cutting machine with laminating is a versatile and efficient machine used in the printing and packaging industry. This machine is designed to cut large rolls of paper, film, or other materials into sheets of desired sizes while also laminating them for added protection and durability.

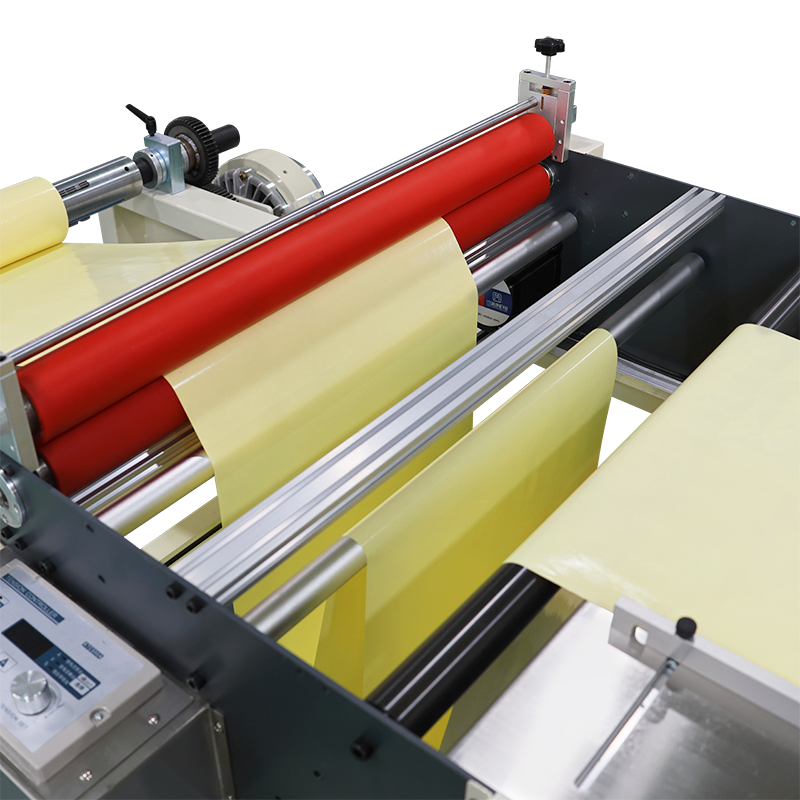

The roll to sheet cutting machine with laminating typically consists of a feeding system that feeds the roll of material into the machine, a cutting mechanism that cuts the material into sheets, and a laminating unit that applies a protective film onto the sheets. The machine is equipped with sensors and controls to ensure precise cutting and laminating processes.

This machine is ideal for producing high-quality sheets for various applications such as labels, stickers, packaging materials, and more. It offers fast production speeds, accurate cutting, and consistent lamination, making it a valuable asset for businesses looking to streamline their production processes and improve product quality.

Overall, the roll to sheet cutting machine with laminating is a reliable and efficient solution for businesses looking to enhance their printing and packaging capabilities.

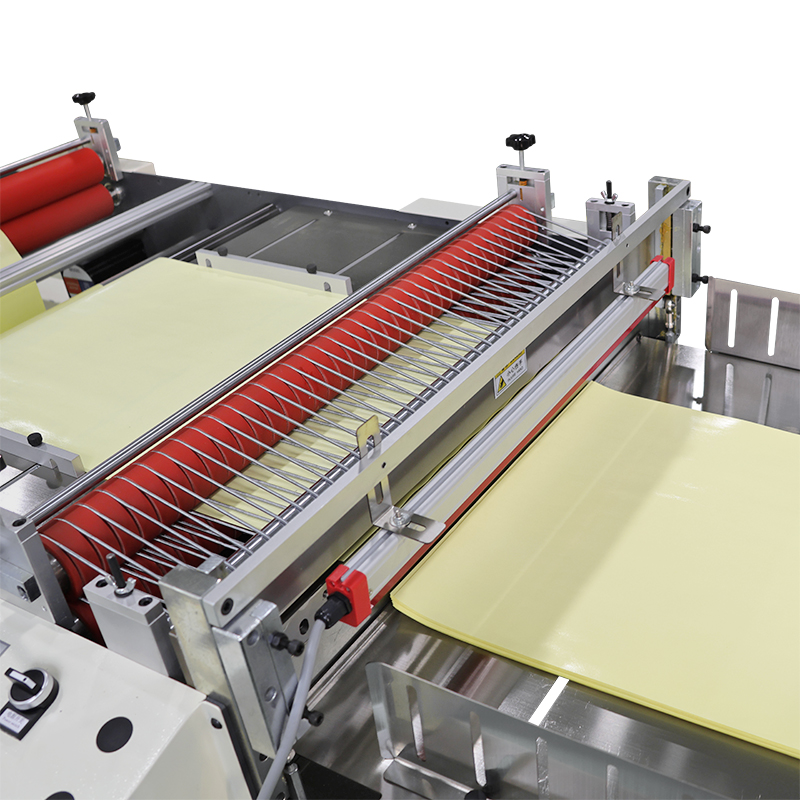

1. Precision Slitting: Equipped with high-precision slitting blades that can accurately slit the rolled materials into the desired widths. The slitting process is highly consistent, ensuring minimal variation in the width of the strips.

2. Adjustable Slitting Width: Operators can easily adjust the slitting width according to their specific requirements. This provides great flexibility in producing different types of sheet products with varying widths.

3. Automatic Tension Control: Maintains a constant tension of the rolled material during the slitting and cutting process. This helps in achieving smooth operation and prevents the materials from wrinkling or tearing.

4. High-Speed Operation: The machine is capable of operating at high speeds, significantly increasing the production efficiency. It can process large volumes of rolled materials in a short period.

5. Integrated Cutting System: After slitting, the machine can directly cut the strips into sheets of the required lengths. This integrated system reduces the need for additional equipment and simplifies the production process.

1. Paper and Cardboard Industry: Used to slit paper and cardboard rolls into narrower strips for the production of products such as paper towels, toilet paper, and cardboard boxes. The slitting and cutting process ensures precise dimensions for these products.

2. Plastic Film Industry: Ideal for slitting plastic films into narrower widths for applications like plastic bags, shrink wraps, and laminates. The machine can handle different types of plastic films with varying thicknesses.

3. Metal Foil Industry: In the metal foil industry, it is used to slit metal foils into strips for applications such as electronics, packaging, and decoration. The precision slitting ensures the quality of the final metal foil products.

4. Textile Industry: Can slit fabric rolls into narrower strips for further processing, such as making ribbons, bias tapes, and other textile accessories. The adjustable slitting width allows for customization according to the specific needs of the textile products.

5. Packaging Industry: For packaging materials like adhesive tapes, labels, and wrapping papers, the slitting and cutting process carried out by this machine ensures the correct dimensions and quality of the final products, which are essential for effective packaging.

How do I maintain a roll-to-sheet cutting machine?