| Availability: | |

|---|---|

| Quantity: | |

HDK-600Z

HDK

8441100000

Roll To Sheet Cutting Machine is a specialized model designed for cutting sensitive materials. It is equipped with special features to ensure the integrity and quality of the materials during the cutting process. The machine is suitable for industries that require high precision and gentle handling of materials, such as the medical and electronics industries.

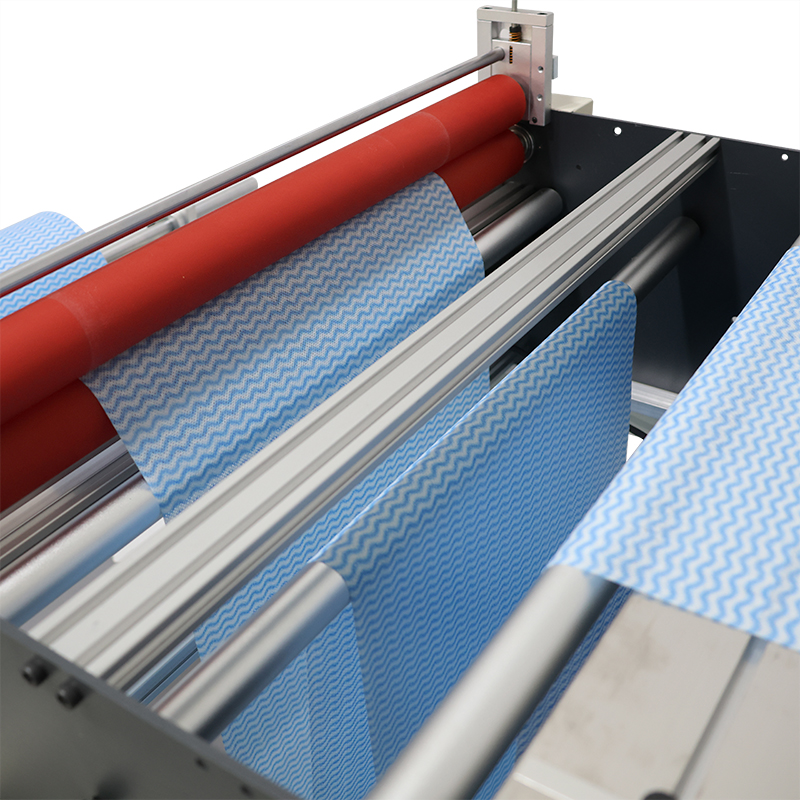

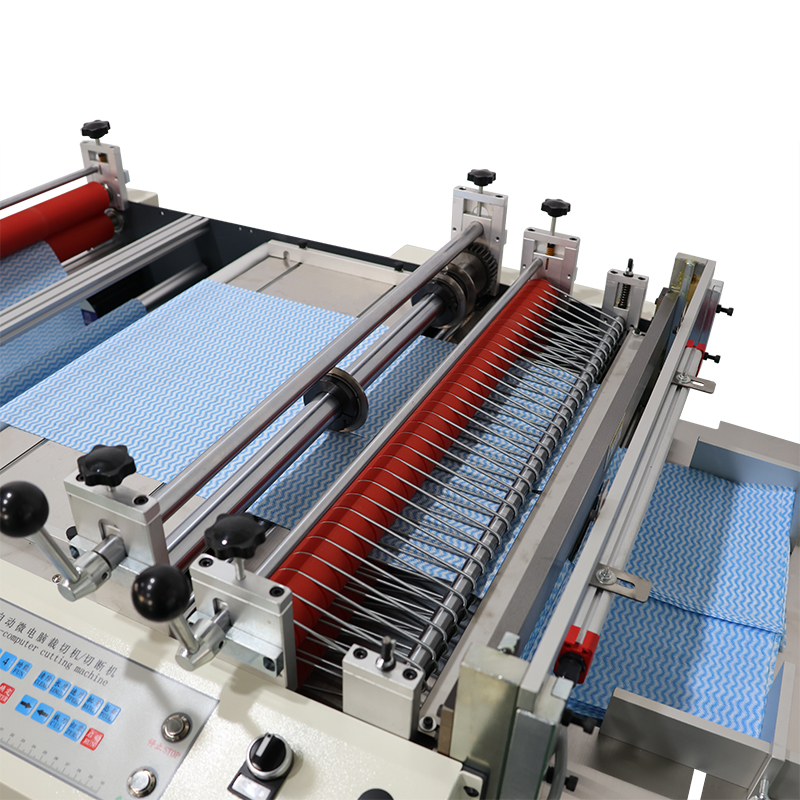

1. Gentle Cutting: The cutting mechanism is designed to cut sensitive materials gently, minimizing the damage to the materials and ensuring their quality.

2. Anti-Static Design: It has an anti-static design to prevent static electricity from affecting the materials, especially for electronic materials.

3. High Precision Sensors: Equipped with high precision sensors that can detect the thickness and properties of the materials, allowing for precise cutting adjustments.

4. Clean Cutting Environment: The machine is designed to maintain a clean cutting environment, preventing dust and debris from contaminating the materials.

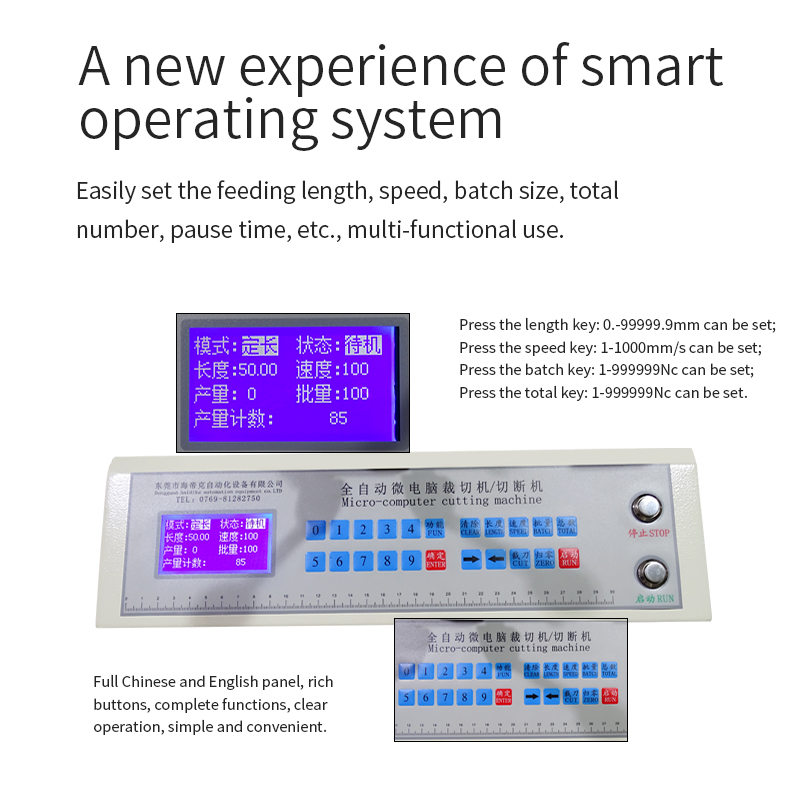

5. Customizable Cutting Parameters: Operators can customize the cutting parameters according to the specific requirements of different sensitive materials, ensuring the best cutting results.

1. Medical Device Manufacturing: Used to cut medical-grade materials, such as surgical drapes, medical films, and disposable medical products, with high precision and quality.

2. Electronics Component Manufacturing: Ideal for cutting electronic materials, such as circuit board laminates, flexible printed circuits, and semiconductor packaging materials.

3. Pharmaceutical Packaging: Can cut pharmaceutical packaging materials, such as blister packaging films and paperboard, ensuring the safety and quality of pharmaceutical products.

4. Optical Industry: Used to cut optical materials, such as optical films and lenses, with high precision and minimal damage.

5. Biotechnology Industry: Suitable for cutting biological materials, such as cell culture membranes and biological sensors, with gentle handling.

How do I maintain a roll-to-sheet cutting machine?