| Availability: | |

|---|---|

| Quantity: | |

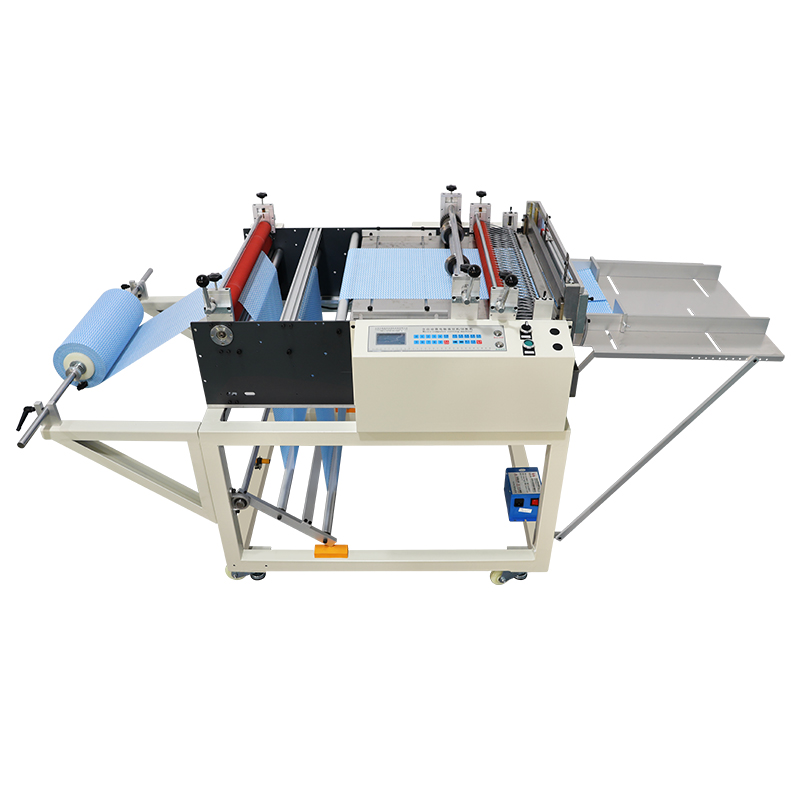

HDK-500ZC

HDK

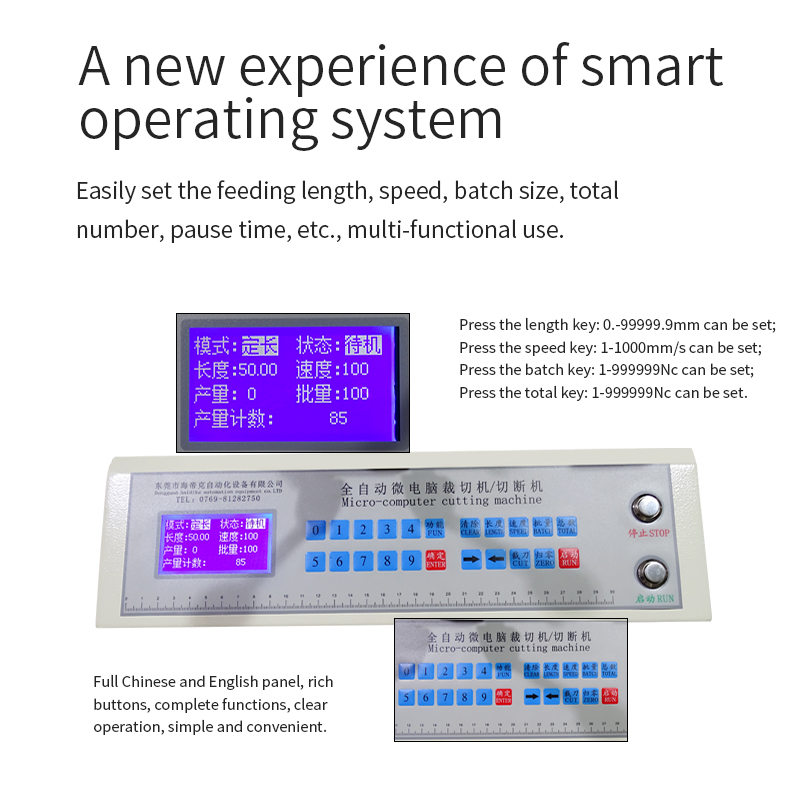

Our Punching Cutting Machine represents the pinnacle of engineering excellence in the manufacturing of precision cutting and punching equipment. The advanced CNC system at its core is not only capable of executing pre-programmed tasks with astonishing accuracy but also offers real-time adjustments during operation. This adaptability is crucial when dealing with variations in material thickness, hardness, or unexpected obstacles during the cutting and punching process.

The machine's structural integrity is further enhanced by its stress-relieved construction. After the frame is fabricated from high-grade alloy steel, it undergoes a specialized heat treatment process to eliminate internal stresses. This ensures that the machine remains stable and accurate over extended periods of use, even under heavy loads and high-intensity operations.

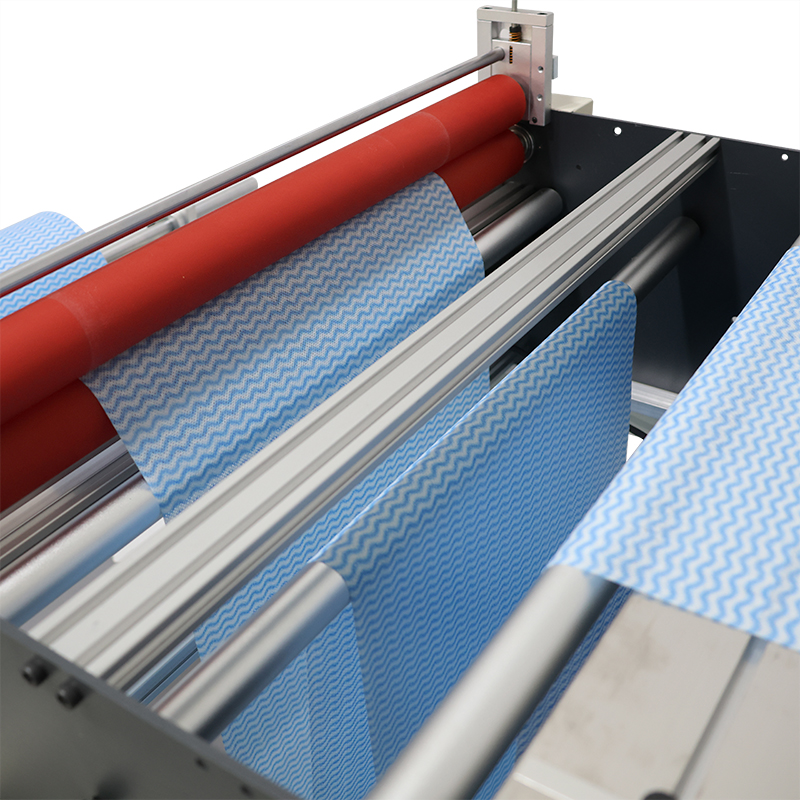

The cutting and punching heads are modular and interchangeable, allowing for a wide range of tooling options. This versatility means that the machine can be quickly configured to handle different materials and production requirements. For example, when working with softer materials like rubber sheets, a set of specialized cutting blades can be installed, while for metal sheets, more robust punching tools can be utilized.

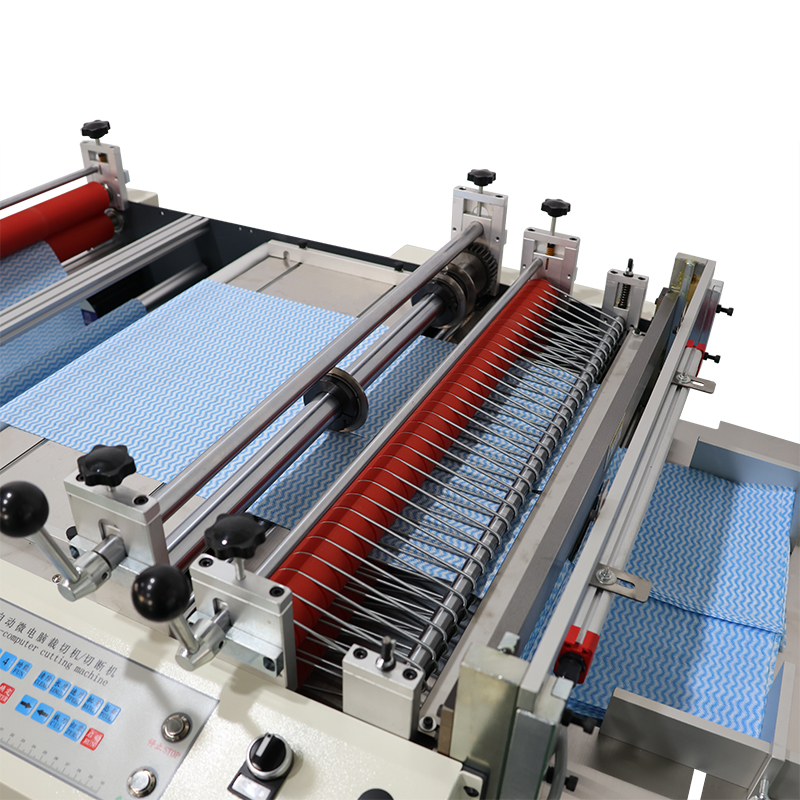

1. Advanced Servo Motor Technology: The servo motors powering the movement of the cutting and punching heads offer unparalleled precision and speed control. These motors are capable of rapid acceleration and deceleration, enabling the machine to perform complex cutting and punching patterns in a fraction of the time compared to traditional machines. Additionally, they provide real-time feedback on the position and movement of the heads, ensuring that every cut and punch is executed with pinpoint accuracy.

2. Intelligent Collision Detection System: Safety is a top priority, and our machine is equipped with an intelligent collision detection system. This system uses a combination of sensors and software algorithms to detect any potential collisions between the cutting or punching heads and the material or other components of the machine. In the event of a detected collision, the machine automatically stops, preventing damage to the equipment and ensuring the safety of the operator.

3. High-Precision Linear Guides: The linear guides used in the machine's movement system are of the highest quality. They provide smooth and accurate linear motion, reducing friction and wear. This results in improved cutting and punching accuracy, as well as a longer lifespan for the machine's moving components. The linear guides are also designed to be easily lubricated, further enhancing their performance and reducing maintenance requirements.

1. Military Equipment Manufacturing: In the production of military equipment, where precision and reliability are non-negotiable, our Punching Cutting Machine plays a vital role. It is used to cut and punch components for weapons systems, armored vehicles, and communication equipment. The ability to handle a variety of materials, including high-strength alloys and composite materials, makes it an essential tool in this demanding industry.

2. Musical Instrument Production: Musical instrument manufacturers rely on the precision of our Punching Cutting Machine to create components for instruments such as guitars, pianos, and drums. For example, it can be used to cut and shape the wooden parts of a guitar body with intricate designs, or to punch holes for the strings and tuning pegs. The high level of accuracy ensures that the instruments produced have excellent sound quality and playability.

3. Architectural Metalwork: In architectural metalwork, our machine is used to create decorative and structural metal components for buildings. From intricate metal railings and gates to large-scale metal panels, the Punching Cutting Machine can bring architectural designs to life with precision. It can cut and punch metal sheets into complex shapes and patterns, adding a touch of elegance and functionality to architectural projects.

How do I maintain a roll-to-sheet cutting machine?