| Availability: | |

|---|---|

| Quantity: | |

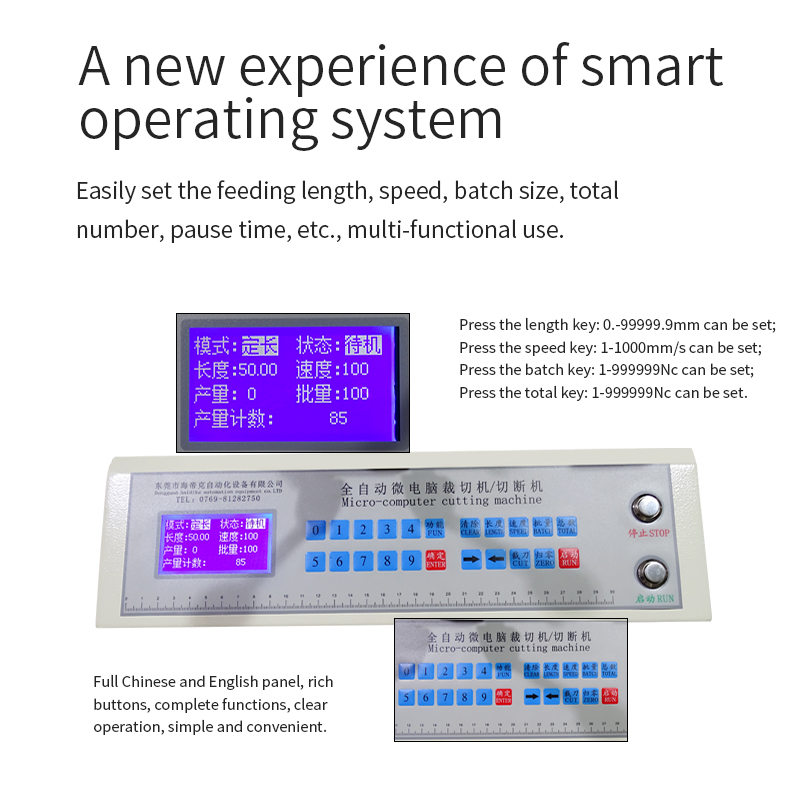

HDK-1000ZC

HDK

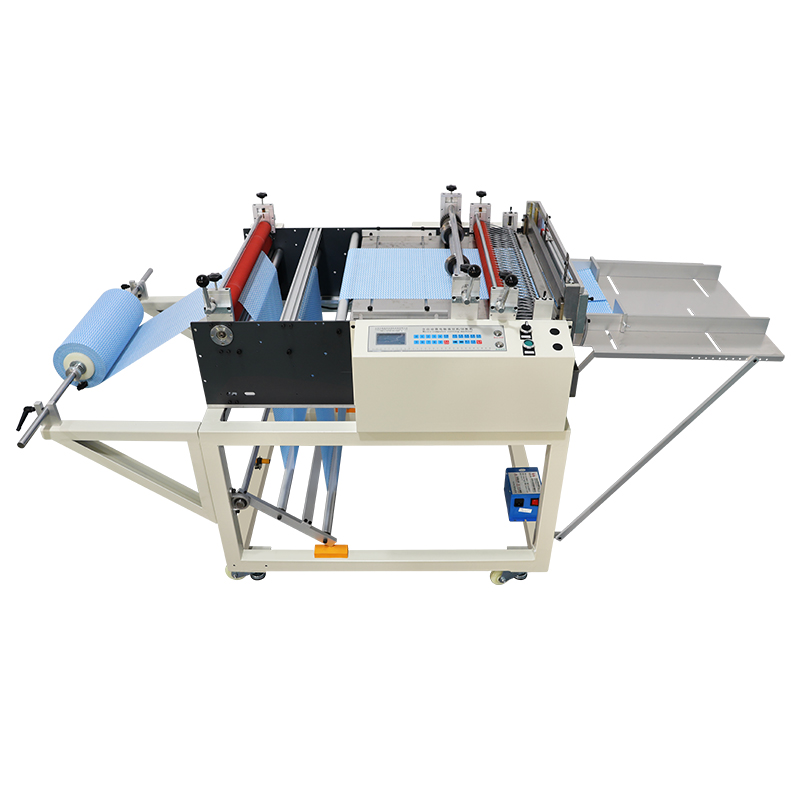

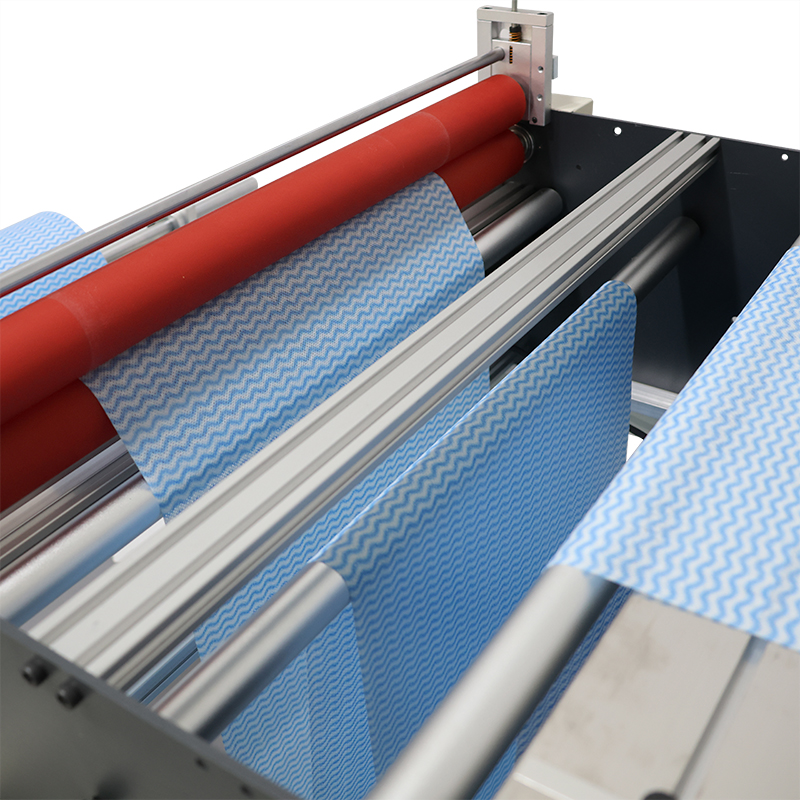

The Roll To Sheet Cutting Machine is a sophisticated industrial solution that combines mechanical prowess with intelligent automation. The unwind system, responsible for feeding the rolled material onto the machine, is equipped with a torque control mechanism. This mechanism ensures that the material is unwound at a consistent speed and tension, preventing any stretching or sagging that could affect the quality of the cut sheets. The unwind system also features an automatic splicing function, allowing for seamless transition between rolls without interrupting the cutting process.

The cutting bed of the machine is made from a high-density, vibration-damping material. This material helps to minimize vibrations during the cutting process, ensuring that the cuts are smooth and accurate. The bed surface is also coated with a special anti-adhesive layer, preventing the material from sticking to the surface and making it easier to remove the cut sheets.

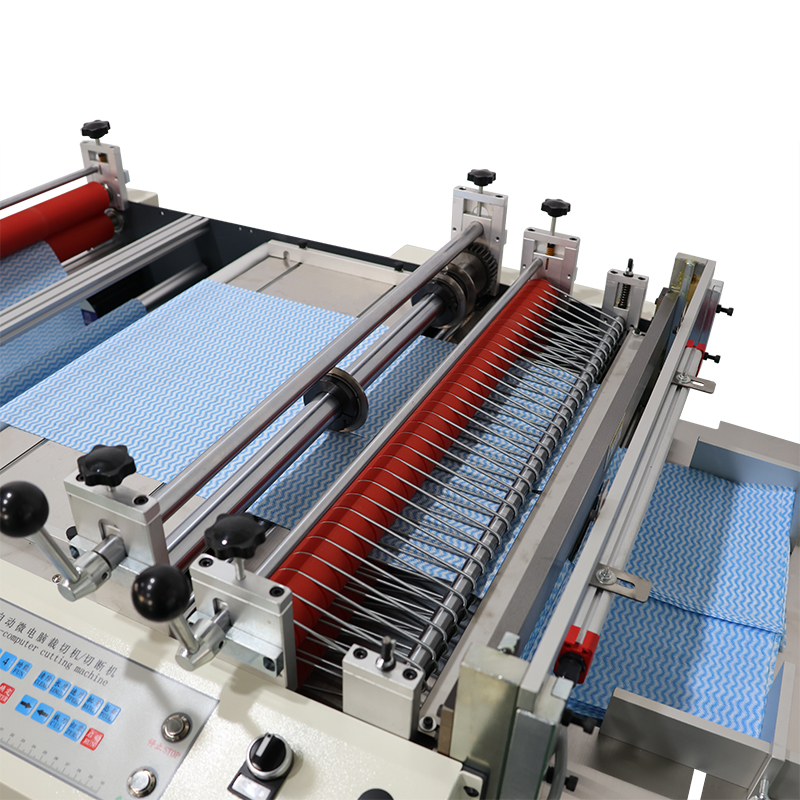

The cutting head is a complex assembly that houses the cutting blade and the drive mechanism. The blade is mounted on a precision linear guide system that allows for smooth and accurate movement in multiple directions. The drive mechanism is powered by a high-torque servo motor that provides the necessary force to cut through the material. The cutting head also features a blade height adjustment mechanism, which allows operators to adjust the cutting depth according to the thickness of the material.

1. Adaptive Cutting Algorithm: Our Roll To Sheet Cutting Machine utilizes an adaptive cutting algorithm that can adjust the cutting speed and blade pressure based on the material being processed. This algorithm takes into account factors such as the material's thickness, density, and elasticity. For example, when cutting a thick and dense material, the algorithm will increase the blade pressure and reduce the cutting speed to ensure a clean cut. Conversely, for a thin and elastic material, it will decrease the blade pressure and increase the cutting speed. This adaptive cutting algorithm not only improves the quality of the cuts but also extends the lifespan of the cutting blade.

2. Integrated Quality Control System: The machine is equipped with an integrated quality control system that uses a combination of sensors and cameras to monitor the cutting process. The sensors can detect any irregularities in the material, such as thickness variations or impurities, while the cameras can visually inspect the cuts for accuracy and quality. If any issues are detected, the system can automatically stop the machine, alert the operator, and provide detailed diagnostic information to help resolve the problem. This integrated quality control system ensures that only high-quality cut sheets are produced.

3. Energy Recovery System: In an effort to reduce energy consumption and environmental impact, our Roll To Sheet Cutting Machine is equipped with an energy recovery system. This system captures the energy generated during the braking and deceleration of the machine's moving components and converts it into electrical energy, which can be used to power other parts of the machine or fed back into the electrical grid. This energy recovery system not only saves energy but also reduces the operating costs of the machine.

1. Medical Implant Material Preparation: In the medical implant industry, where the materials used must meet strict biocompatibility and precision requirements, our Roll To Sheet Cutting Machine is used to cut sheets of materials such as titanium, stainless steel, and medical-grade polymers into the required shapes and sizes for implants. The machine's high precision and clean cutting capabilities ensure that the implant materials are free from contaminants and have the exact dimensions needed for successful implantation.

2. High-Performance Composite Material Processing for Racing Cars: For racing car manufacturers, who rely on high-performance composite materials to achieve maximum speed and performance, our machine is used to cut composite sheets into the complex shapes required for aerodynamic components, such as wings, spoilers, and body panels. The machine's ability to handle composite materials with precision and the adaptive cutting algorithm's ability to optimize the cutting process for these materials make it an essential tool in this demanding industry.

3. Flexible Display Manufacturing: In the flexible display manufacturing industry, where materials such as flexible OLEDs and thin-film transistors are used, our Roll To Sheet Cutting Machine is used to cut these delicate materials into the required sizes and shapes. The machine's gentle cutting action, precision control, and integrated quality control system ensure that the flexible display materials are not damaged during the cutting process, maintaining their functionality and performance.

How do I maintain a roll-to-sheet cutting machine?