| Availability: | |

|---|---|

| Quantity: | |

HDK-200S

HDK

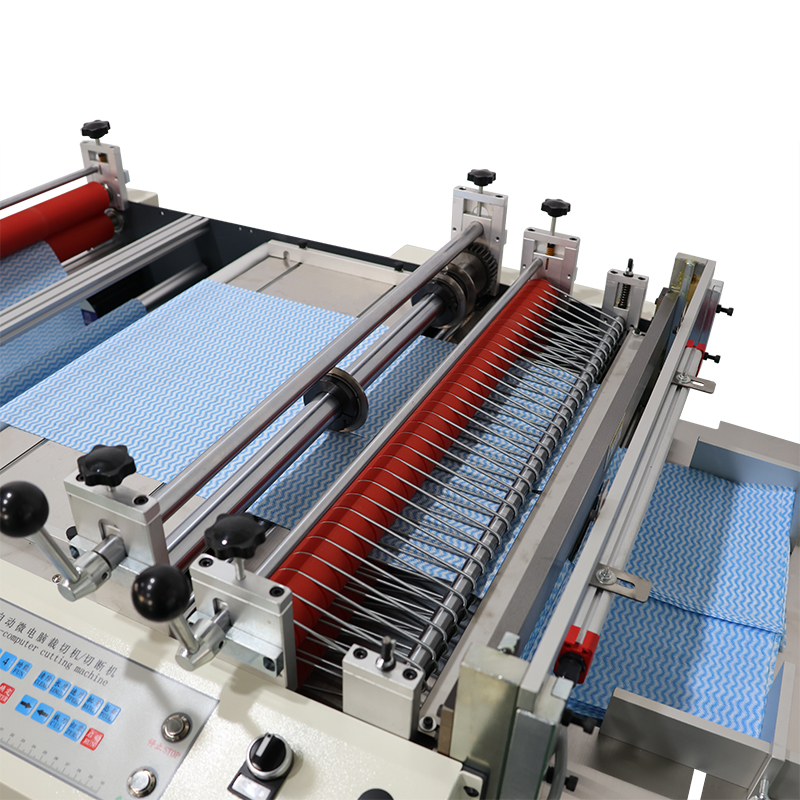

The Table Roll To Sheet Cutting Machine is a unique and practical piece of equipment designed for smaller-scale or more flexible cutting operations. It features a table-like structure on which the rolled material is placed and processed. This machine is highly suitable for businesses that need to cut rolls of materials into sheets in a more manual or semi-automated way, offering a balance between simplicity and functionality. It can handle a variety of materials such as thin paper, fabric, and some lightweight plastic films.

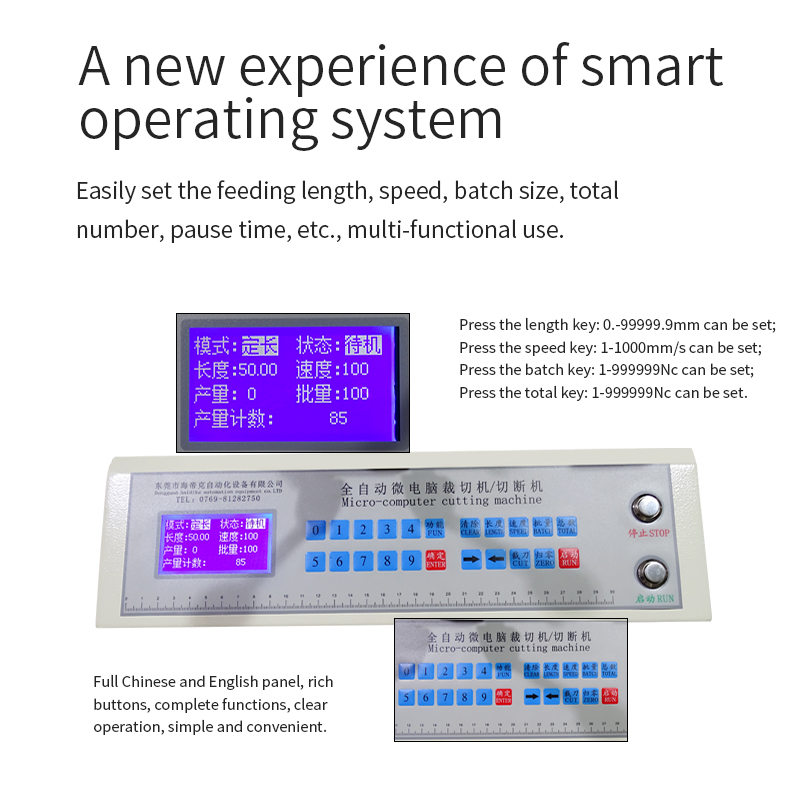

1. Manual and Semi-Automated Operation: It allows for both manual control, where operators can guide the cutting process, and semi-automated operation, which can be set up for more repetitive tasks. This flexibility makes it suitable for different types of cutting jobs, from one-off custom cuts to small production runs.

2. Adjustable Cutting Table: The cutting table can be adjusted in height and angle, enabling operators to work comfortably and to achieve the best cutting results depending on the material and the cutting requirements.

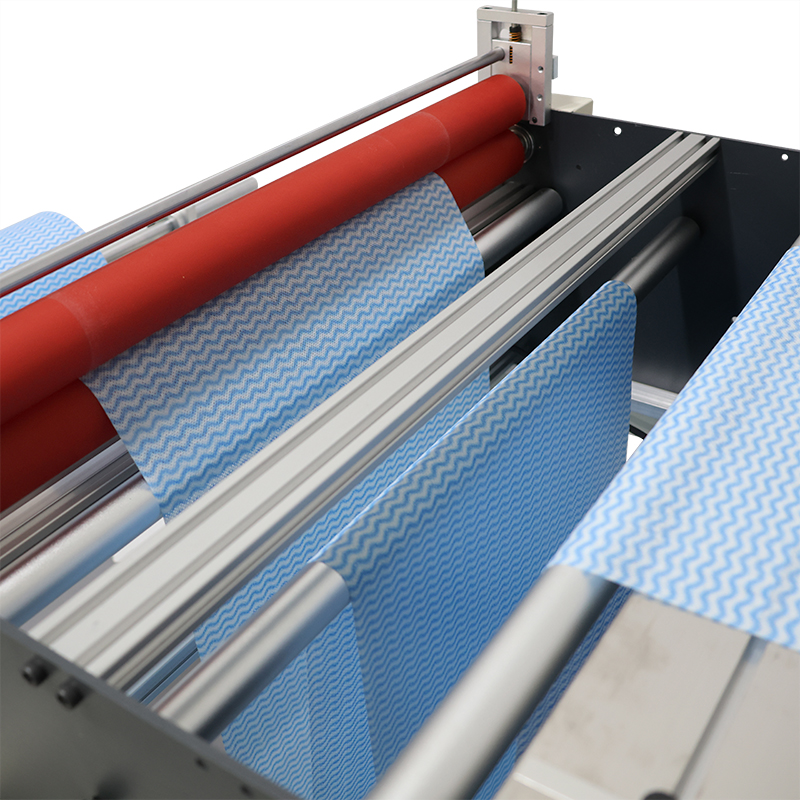

3. Precision Cutting Blades: Equipped with precision cutting blades that can be easily replaced when worn out. These blades ensure clean and accurate cuts on the materials being processed.

4. Compact and Portable: Its compact design makes it easy to move around the workshop or production area. It can be easily transported to different locations if needed, making it a convenient option for businesses with multiple workspaces.

5. Safety Features: It is equipped with basic safety features such as blade guards to protect operators from accidental cuts during the operation.

1. Art and Craft Studios: Artists and crafters can use this machine to cut various materials like paper, fabric, and thin plastic sheets for their creative projects. The manual control option allows for more artistic and customized cutting.

2. Small Tailoring Shops: Tailors can cut fabric rolls into sheets of the required sizes for making clothes, accessories, and home textiles. The adjustable table helps in handling different types of fabrics more easily.

3. Printing and Binding Workshops: In small printing and binding workshops, it can be used to cut printed paper rolls into sheets for further processing, such as bookbinding or creating brochures.

4. Home-Based Manufacturing: For home-based businesses that produce small quantities of products, this machine can be used to cut materials like packaging materials or fabric for handmade products.

5. Educational Institutions: Schools and vocational training centers can use this machine to teach students about material cutting and processing techniques in various fields such as art, design, and textiles.

How do I maintain a roll-to-sheet cutting machine?