| Availability: | |

|---|---|

| Quantity: | |

HDK-800ZF

HDK

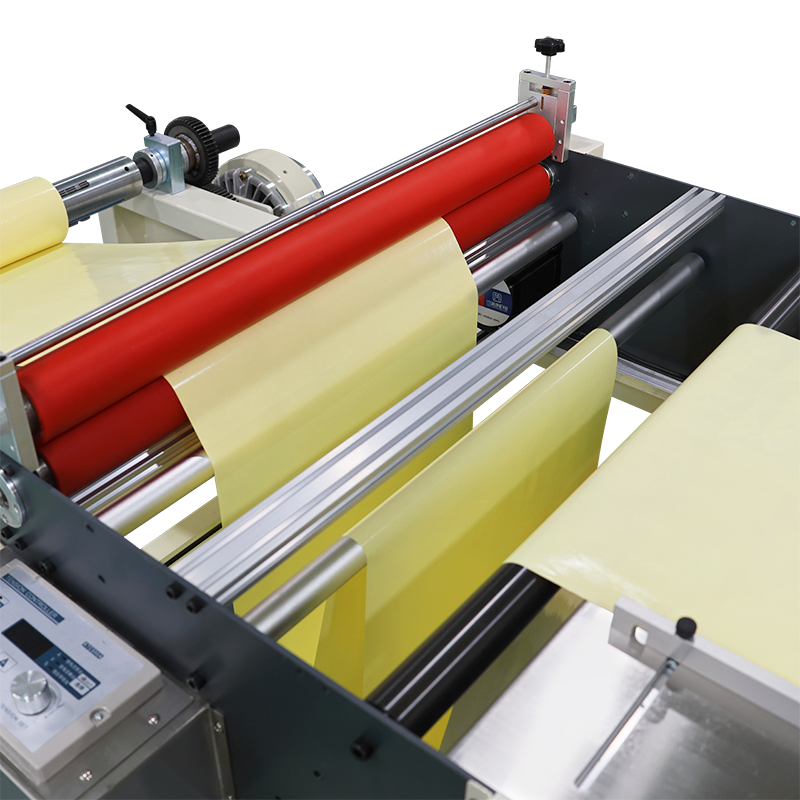

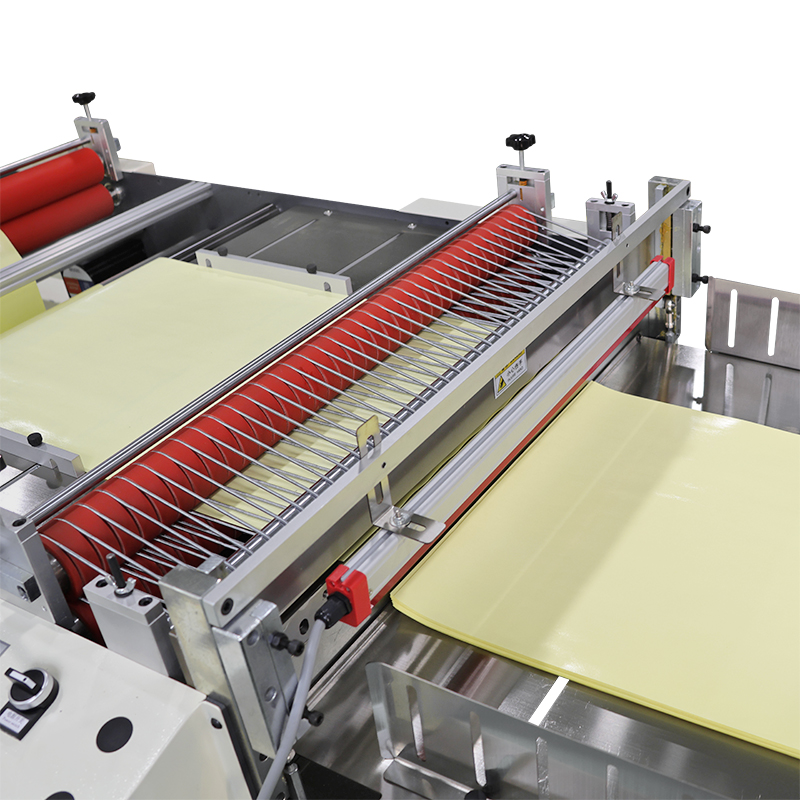

Roll To Sheet Slitting Machine is a high-performance model designed for large-scale industrial production. It is capable of handling high volumes of rolled materials with great efficiency and precision.

1. High Capacity: It can process large rolls of materials at a high speed, meeting the production demands of large industrial enterprises. The machine can handle a wide range of material thicknesses and types.

2. Advanced Automation: The machine is highly automated, with features such as automatic feeding, slitting, and cutting. This reduces the need for manual labor and increases the production efficiency significantly.

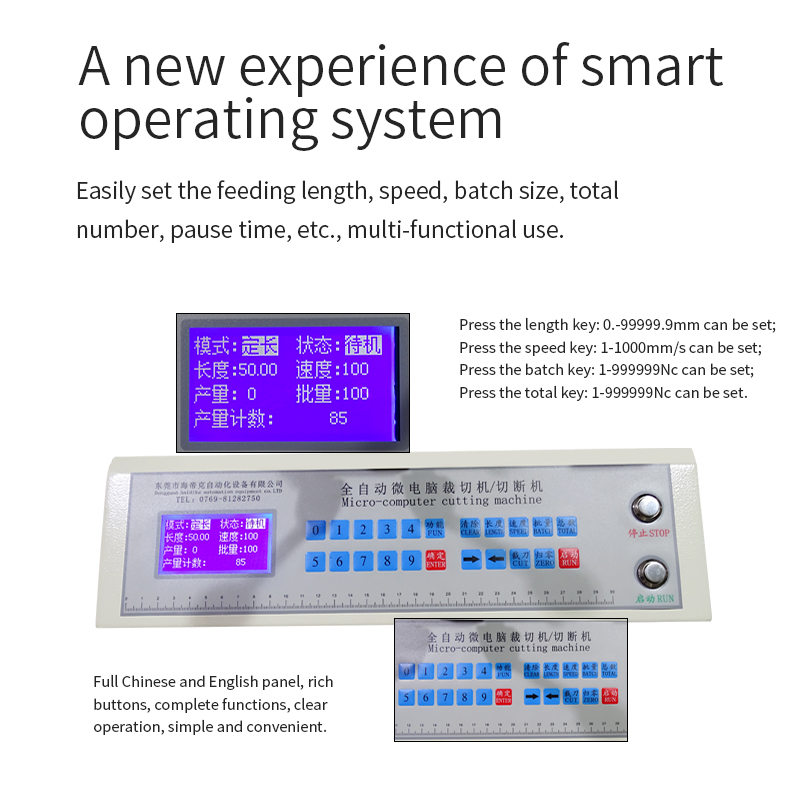

3. Precision Control System: Equipped with a precision control system that ensures accurate slitting width and cutting length. The system can monitor and adjust the operation in real-time to maintain the quality of the products.

4. Modular Design: It has a modular design that allows for easy expansion and customization. Businesses can add additional functions or components according to their specific production needs.

5. Reliable After-Sales Service: Comes with a reliable after-sales service team that provides technical support, maintenance, and spare parts supply. This ensures the normal operation of the machine and minimizes the production downtime.

1. Large Packaging Factories: Used by large packaging factories to slit and cut cardboard, plastic films, and other packaging materials in large quantities. The high capacity and automation features of the machine meet their production requirements.

2. Paper Mills: Paper mills can use this machine to slit paper rolls into narrower widths and cut them into sheets for different paper products. The precision control system ensures the quality of the final paper products.

3. Plastic Manufacturing Plants: In plastic manufacturing plants, it is used to slit and cut plastic rolls into the required widths and lengths for the production of plastic products such as containers, trays, and films.

4. Textile Mills: Textile mills can slit fabric rolls into narrower strips and cut them into sheets for further processing in large-scale production. The modular design of the machine allows for customization according to the specific needs of the textile industry.

5. Metal Processing Plants: For metal processing plants, this machine can slit metal foils and thin metal sheets into the required widths and cut them into sheets for various applications such as electronics, decoration, and construction.

How do I maintain a roll-to-sheet cutting machine?