| Availability: | |

|---|---|

| Quantity: | |

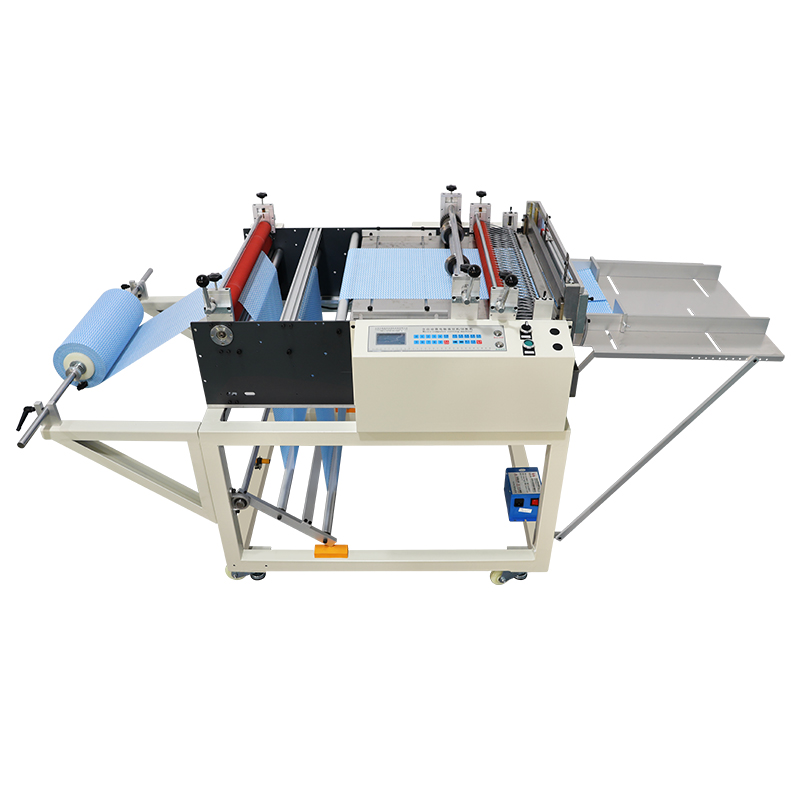

HDK-800ZC

HDK

Our Punching Cutting Machine is not just a standard piece of equipment but a technological marvel engineered for peak performance. The frame of the machine is constructed from high-grade alloy steel, ensuring exceptional durability and stability even during the most demanding cutting and punching operations. The internal mechanisms are meticulously designed with advanced computer numerical control (CNC) technology, enabling seamless integration of the cutting and punching functions. This allows for rapid switching between different tasks, reducing production downtime significantly.

The machine's cutting head is equipped with a multi-axis system that can move with incredible precision in multiple directions. This flexibility enables it to execute complex cutting and punching patterns with ease, whether it's creating intricate designs on metal sheets or making precise holes in plastic components. Additionally, the machine is designed with a modular structure, which means that individual components can be easily replaced or upgraded as technology advances or as specific production needs change.

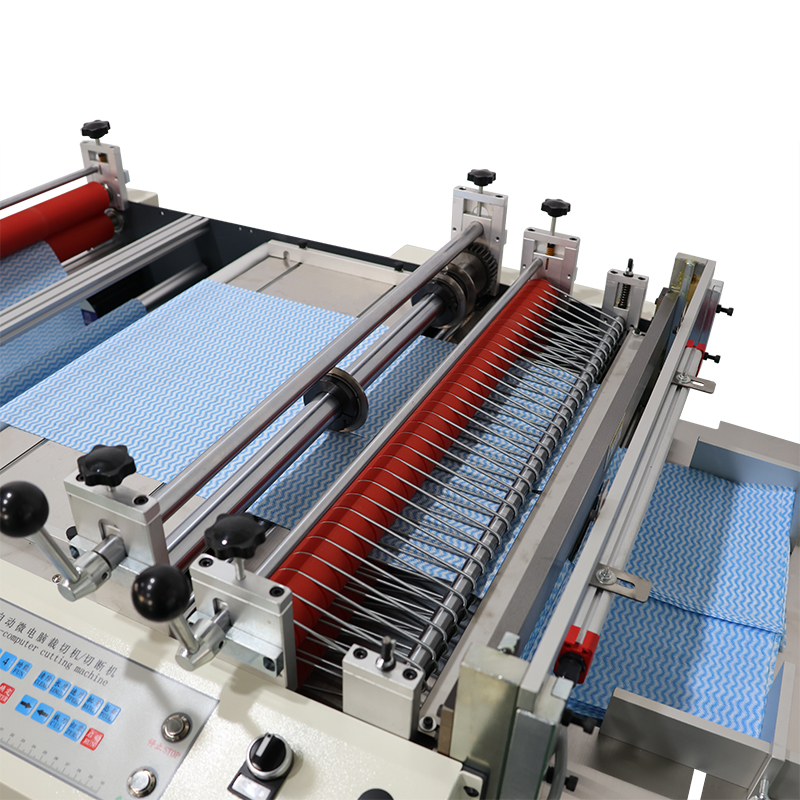

1. Advanced Tooling System: The Punching Cutting Machine comes with an innovative tooling system that allows for quick and easy tool changes. The tools are made from high-speed steel or carbide, ensuring long-lasting sharpness and wear resistance. This not only improves the quality of the cuts and punches but also reduces the time spent on tool maintenance.

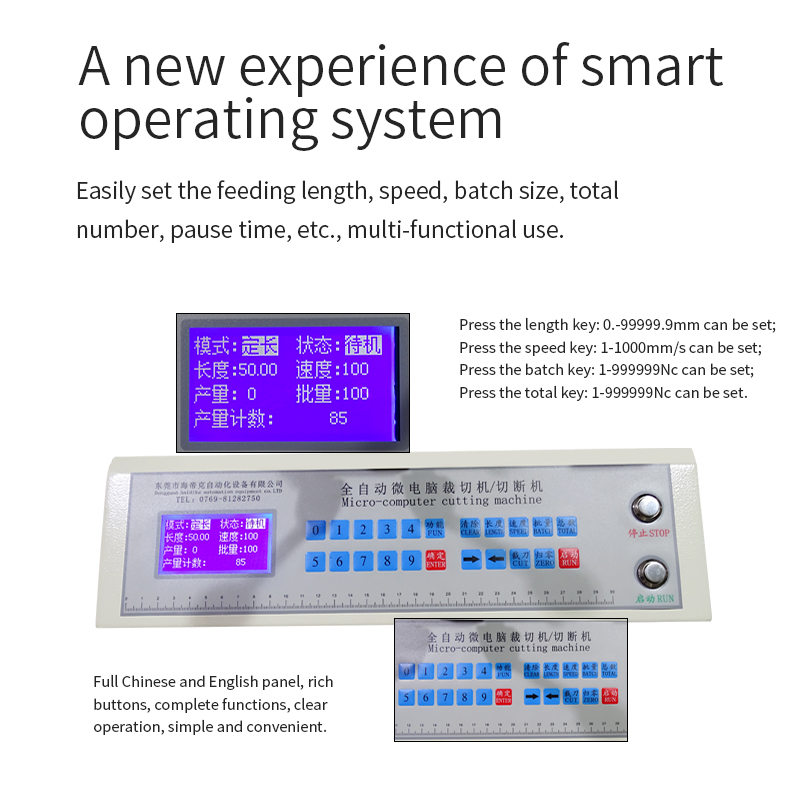

2. Intelligent Software Integration: It is integrated with intelligent software that enables operators to create and edit cutting and punching patterns with ease. The software has a user-friendly interface with features such as drag-and-drop functionality, allowing for quick design implementation. It also supports various file formats, making it compatible with most design software used in the industry.

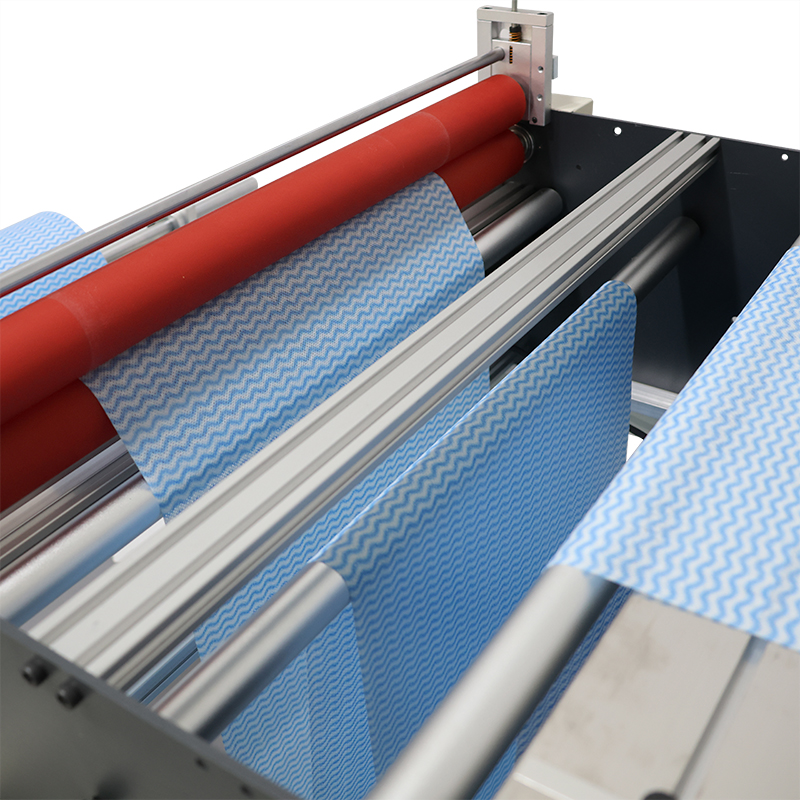

3. High-Speed Operation with Precision: Thanks to its powerful motor and advanced drive system, the machine can operate at high speeds while maintaining exceptional precision. The servo motors used in the machine provide accurate control over the movement of the cutting head, ensuring that each cut and punch is executed with the highest level of accuracy.

4. Energy-Efficient Design: Our machine is designed with energy efficiency in mind. It uses advanced power management techniques to reduce energy consumption without sacrificing performance. This not only helps businesses save on energy costs but also contributes to a more sustainable manufacturing process.

1. Aerospace Industry: In the aerospace sector, precision is of utmost importance. Our Punching Cutting Machine is used to cut and punch lightweight yet strong metal alloys used in aircraft components such as wing spars, fuselage panels, and engine parts. The ability to create complex shapes and precise holes is crucial for ensuring the structural integrity and aerodynamic performance of the aircraft.

2. Jewelry Manufacturing: For jewelry manufacturers, the machine can be used to cut and punch precious metals like gold, silver, and platinum. It allows for the creation of intricate designs and patterns on jewelry pieces, adding a touch of uniqueness and artistry. The high precision of the machine ensures that even the smallest details are accurately reproduced.

3. Automotive Aftermarket: In the automotive aftermarket, there is a high demand for custom parts. Our Punching Cutting Machine enables manufacturers to produce custom metal and plastic components for car modifications, such as custom grilles, interior trim pieces, and engine covers. The ability to quickly switch between different cutting and punching tasks makes it ideal for small-batch production of these custom parts.

How do I maintain a roll-to-sheet cutting machine?