Fully Automatic Non-woven Fabric Roll To Sheet Hole Pneumatic Punching Cutting Machine

| Availability: | |

|---|---|

| Quantity: | |

-

HDK-800ZC

-

HDK

Product Description

The Punching Cutting Machine is a highly efficient and versatile piece of equipment designed to meet the diverse cutting and punching needs in various industries. It combines advanced technology with a robust construction to ensure precise and consistent performance. This machine is capable of handling a wide range of materials, including metal sheets, plastic sheets, and rubber sheets. With its user-friendly interface and intuitive controls, operators can easily set up and execute cutting and punching tasks with minimal effort.

Key Features

1. High Precision: Equipped with state-of-the-art cutting and punching mechanisms, this machine can achieve extremely accurate results, ensuring minimal material waste.

2. Versatility: It can perform a variety of cutting and punching operations, such as straight cuts, curved cuts, and different shapes of holes punching.

3. Automation: The machine is highly automated, reducing the need for manual intervention and increasing productivity. It can work continuously for long periods without significant fatigue.

4. Safety Features: Safety is a top priority. It is equipped with emergency stop buttons, safety guards, and sensors to protect operators from potential hazards.

5. Customization: It can be customized according to the specific requirements of customers, such as the size of the working area, the type of materials to be processed, and the specific cutting and punching patterns.

Applications

1. Automotive Industry: Used for cutting and punching metal components for car bodies, engines, and other parts.

2. Electronics Industry: Ideal for processing plastic and metal sheets for electronic enclosures, circuit boards, and other electronic components.

3. Furniture Industry: Can be used to cut and punch materials for furniture manufacturing, such as metal frames and plastic parts.

4. Packaging Industry: Helps in cutting and punching various packaging materials, such as cardboard, plastic films, and foam sheets.

5. Construction Industry: Used for processing metal sheets for construction projects, such as roofing, siding, and structural components.

-

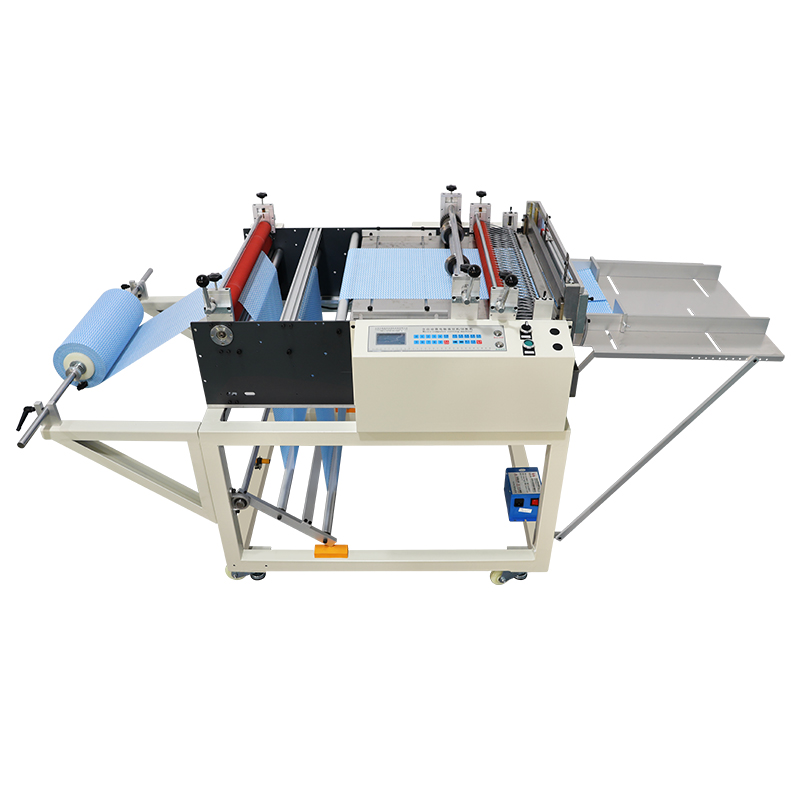

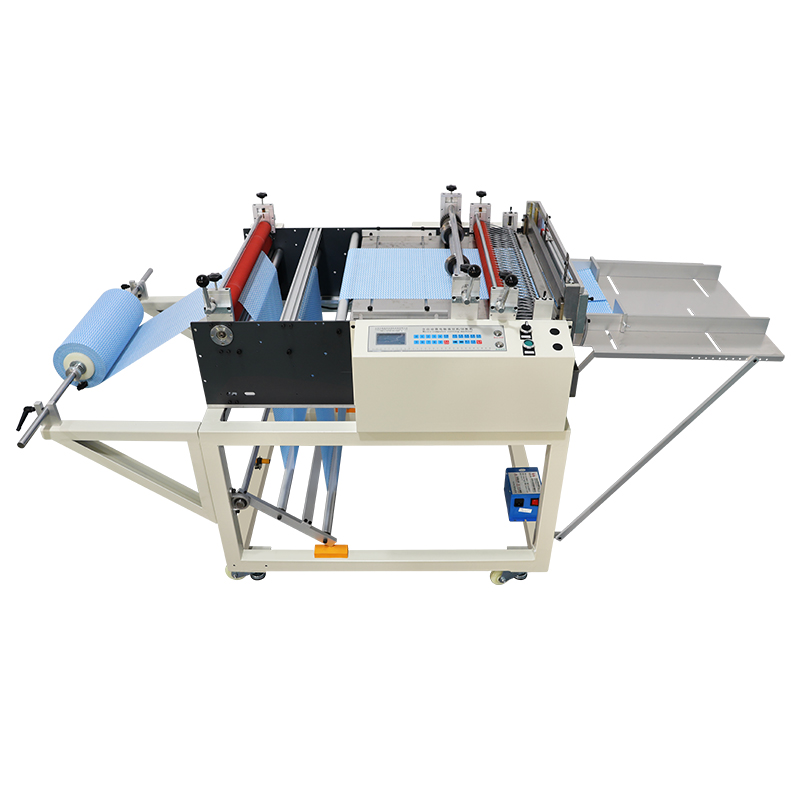

Loading Material Part:The triangular bracket supports loads of up to 50kg, making it ideal for small printed rolls, labeling materials, and similar applications. It’s a suitable option if your raw material rolls weigh 50kg or less.

Loading Material Part:The triangular bracket supports loads of up to 50kg, making it ideal for small printed rolls, labeling materials, and similar applications. It’s a suitable option if your raw material rolls weigh 50kg or less. -

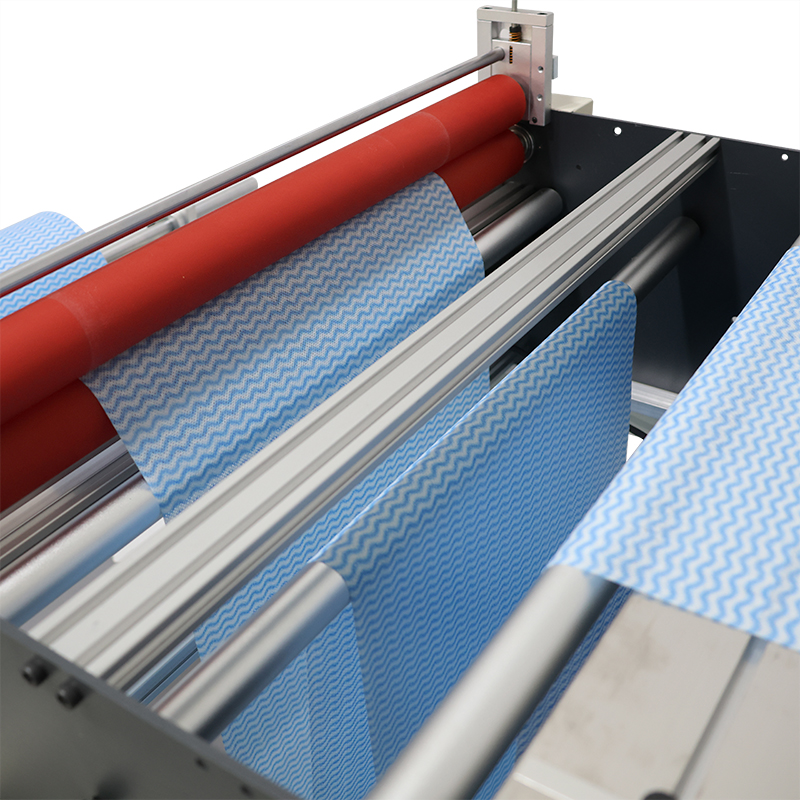

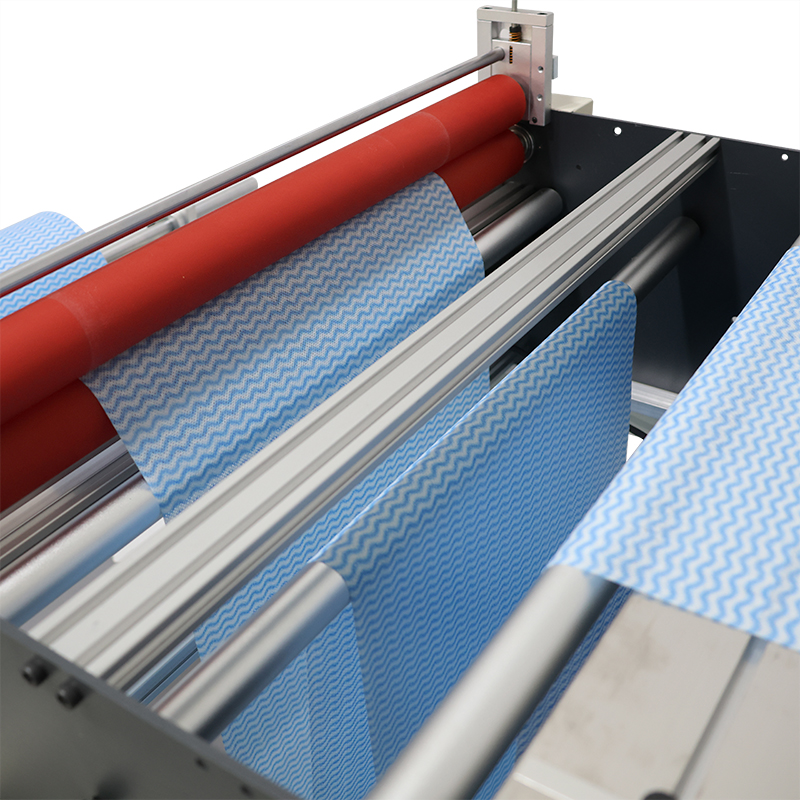

Automatic Feeding System:Our system now features automatic feeding rollers. The unwind photoelectric sensor detects swing arm movement and sends signals to the rubber rollers, which automatically adjust their speed to ensure smooth and synchronized feeding.

Automatic Feeding System:Our system now features automatic feeding rollers. The unwind photoelectric sensor detects swing arm movement and sends signals to the rubber rollers, which automatically adjust their speed to ensure smooth and synchronized feeding. -

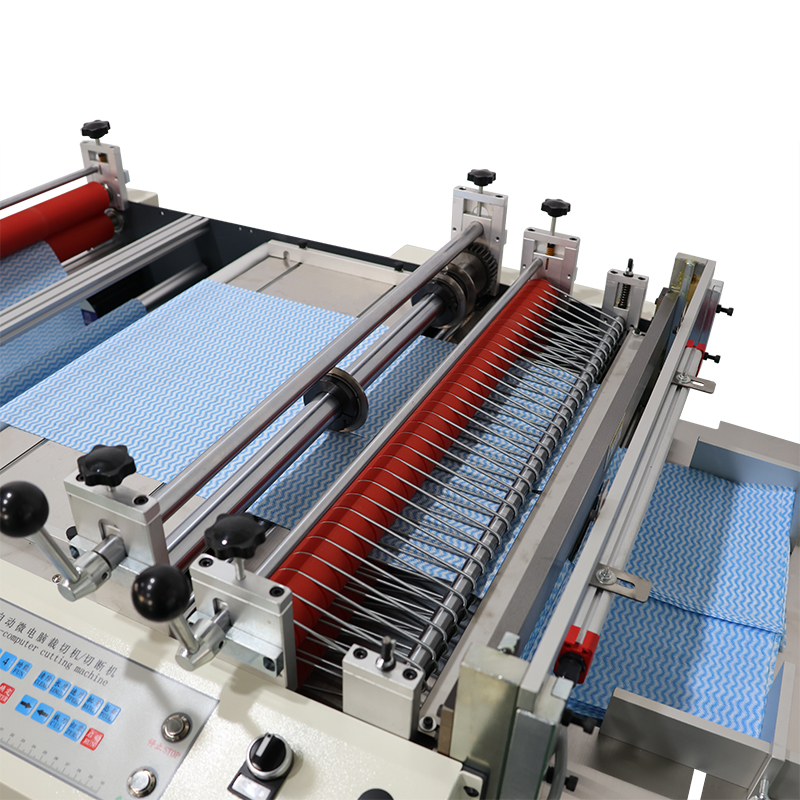

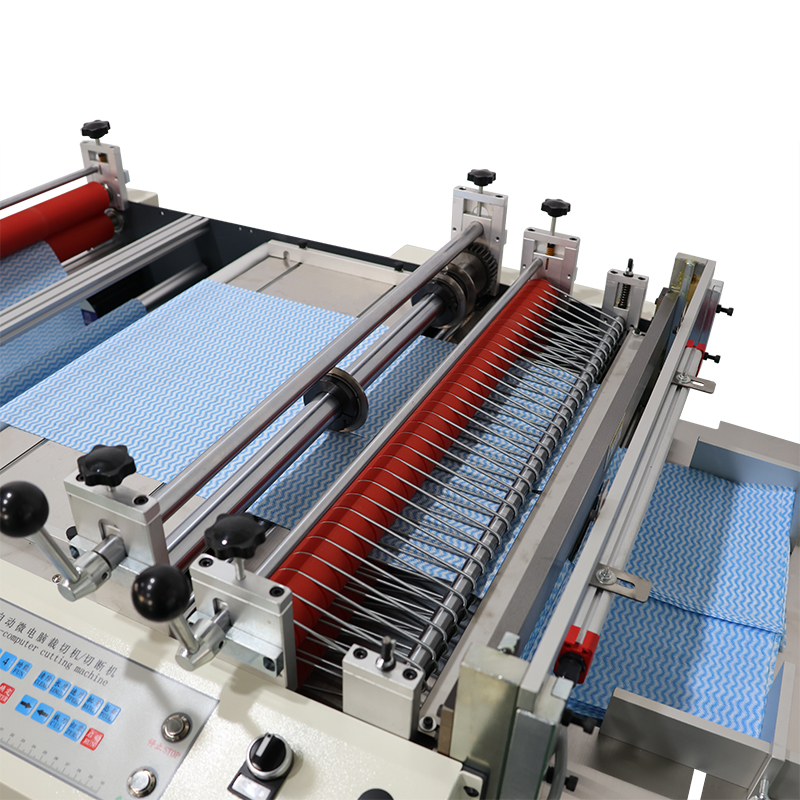

Cutting Knife System:The cutting knife is made of sharp steel and uses a scissor-like up-and-down motion for quick, efficient cutting. It delivers clean, burr-free edges and operates at speeds of up to 80m per minute on high-speed machines.

Cutting Knife System:The cutting knife is made of sharp steel and uses a scissor-like up-and-down motion for quick, efficient cutting. It delivers clean, burr-free edges and operates at speeds of up to 80m per minute on high-speed machines. -

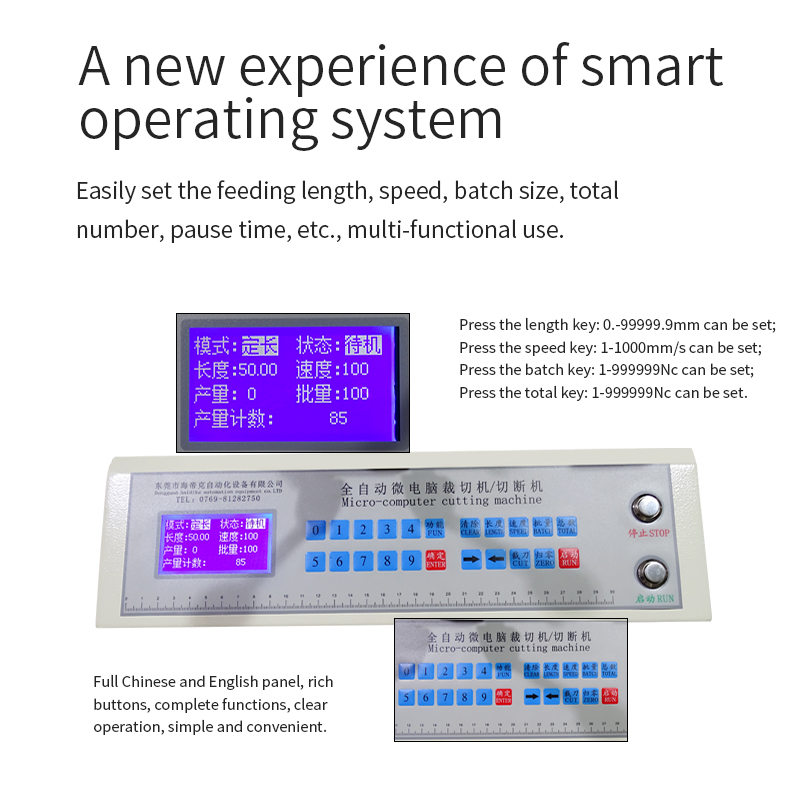

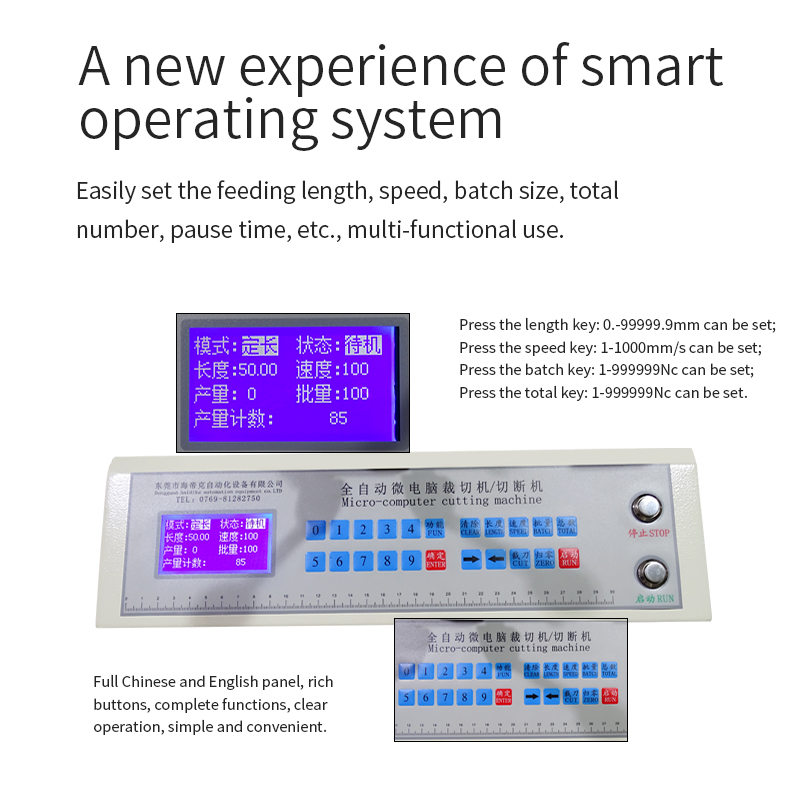

PLD control system:The PLD control system allows for precise adjustment of cutting length and speed, as well as batch quantity settings. It includes a counter to set and track the desired cutting quantity, ensuring accuracy and efficiency during production. The system supports both Chinese and English language options, and additional language customizations can be provided based on customer needs, offering greater flexibility for international users.

PLD control system:The PLD control system allows for precise adjustment of cutting length and speed, as well as batch quantity settings. It includes a counter to set and track the desired cutting quantity, ensuring accuracy and efficiency during production. The system supports both Chinese and English language options, and additional language customizations can be provided based on customer needs, offering greater flexibility for international users.

Applicable Materials

1. Paper Materials: Coated paper, kraft paper, cardstock, self-adhesive paper, etc.

2. Film Materials: PET, PVC, PP, PE, PC, and other plastic films.

3. Foam Materials: EVA foam, sponge, double-sided adhesive tape, etc.

4. Metal Foils: Aluminum foil, copper foil, and other precision materials.

5. Composite Materials: Metallized films, release paper, thermal-sensitive materials, etc.

- 1. What is a roll-to-sheet cutting machine?A roll-to-sheet cutting machine, also known as an auto sheeter, is an industrial device designed to convert flexible roll materials—such as paper, film, foam, or metal foil—into individual sheets of specified dimensions. This equipment is essential in industries like packaging, printing, electronics, advertising, automotive, and medical sectors, ensuring efficient and precise cutting processes.

-

How do I maintain a roll-to-sheet cutting machine?

Regular maintenance includes cleaning the blades, checking the servo motor and control systems, and ensuring proper lubrication to maintain smooth operation and longevity. - What is production lead time?Our standard machines have a production lead time of seven days, while custom machines require a lead time of two weeks.