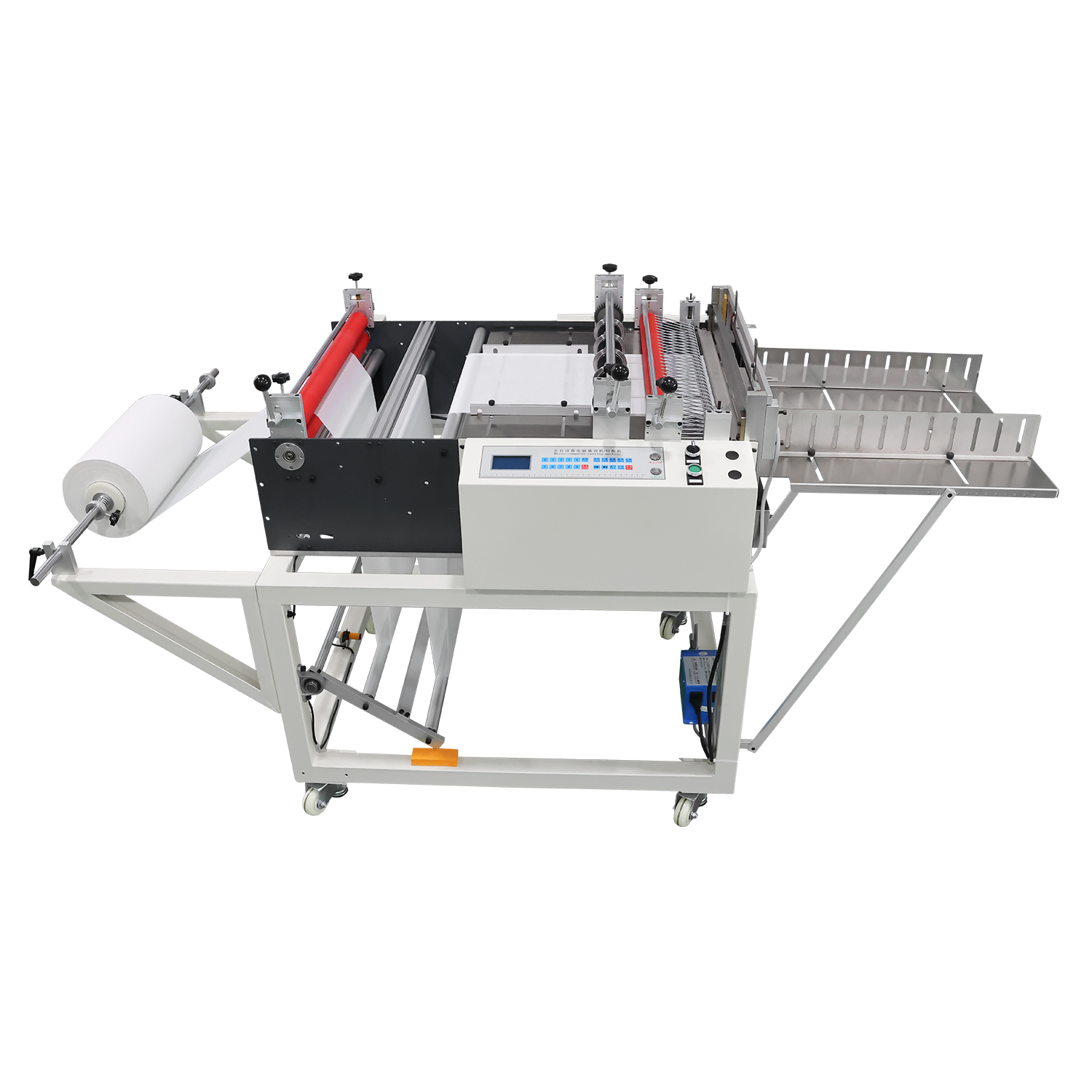

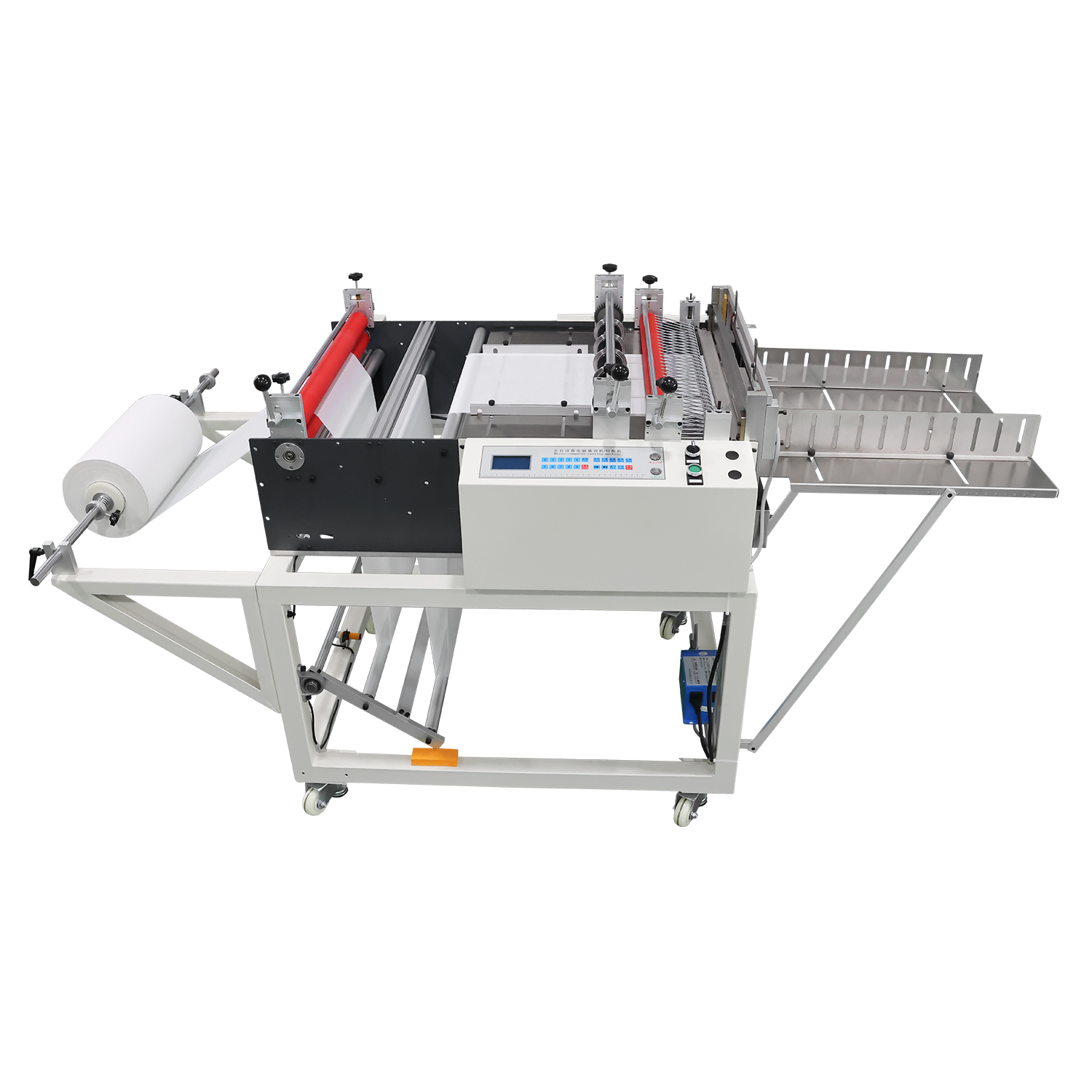

Customized 500mm Non-woven Fabric/PET Film Roll To Sheet Cutter with Pnuematic Punching

| Availability: | |

|---|---|

| Quantity: | |

-

HDK-500ZC

-

HDK

Roll To Sheet Punching Machine And Cutting Machine

Roll to Sheet Punching Machine for Non-Woven Fabric – Precision and Efficiency Combined

If you are looking for a reliable solution to convert non-woven roll materials into punched sheets, a Roll to Sheet Punching Machine for Non-Woven is exactly what your production line needs. Designed for high precision, stable performance, and clean punching, this machine is widely used in hygiene, packaging, medical, and industrial textile industries.

Applications in the Non-Woven Industry

The non-woven roll to sheet punching machine is especially useful in the following sectors:

Medical and Hygiene Products: Face masks, disposable sheets, wet wipes, surgical dressings.

Agricultural Use: Non-woven seedling covers, crop protection sheets.

Packaging: Eco-friendly packaging inserts and liners.

Home Textiles: Pillow inserts, filters, curtains.

Industrial Uses: Insulation, filtration, automotive linings.

Key Features and Advantages

High Precision Cutting: The advanced Japanese eye mark sensor ensures accurate positioning and consistent cutting, even for printed patterns.

Versatile Material Compatibility: Capable of handling a wide range of roll materials, from paper and plastic film to non-woven and aluminum foil.

Efficient Slitting System: Equipped with durable slitting disc blades, supporting clean and sharp slitting without burrs.

Easy Roll Handling: The air shaft design enables quick and secure loading/unloading of rolls, improving operation efficiency.

Compact and User-Friendly Design: Space-saving layout with intuitive controls, suitable for various production environments.

-

Loading partFor small roll materials with a roll weight under 50kg, we recommend using the Triangular Bracket.

Loading partFor small roll materials with a roll weight under 50kg, we recommend using the Triangular Bracket.

Thanks to its triangular structure, the bracket provides excellent stability and load-bearing capacity, ensuring that the material remains steady and properly aligned during the cutting process. The strong geometric design of the triangle helps distribute the weight evenly, minimizing vibrations and improving cutting precision. -

Slitting partRound slitting blades deliver ultra-clean, burr-free cuts for a premium finish.

Slitting partRound slitting blades deliver ultra-clean, burr-free cuts for a premium finish.

High-speed, smooth operation boosts your production efficiency like never before.

Longer blade life means lower maintenance costs and more uptime.

Versatile and reliable, they handle everything from paper to film and foil with ease. -

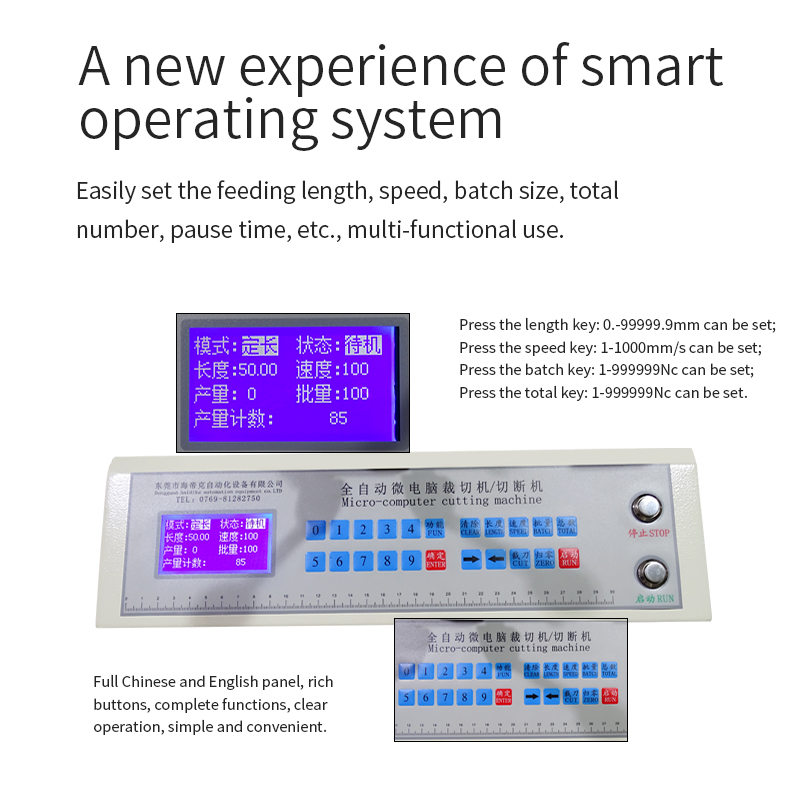

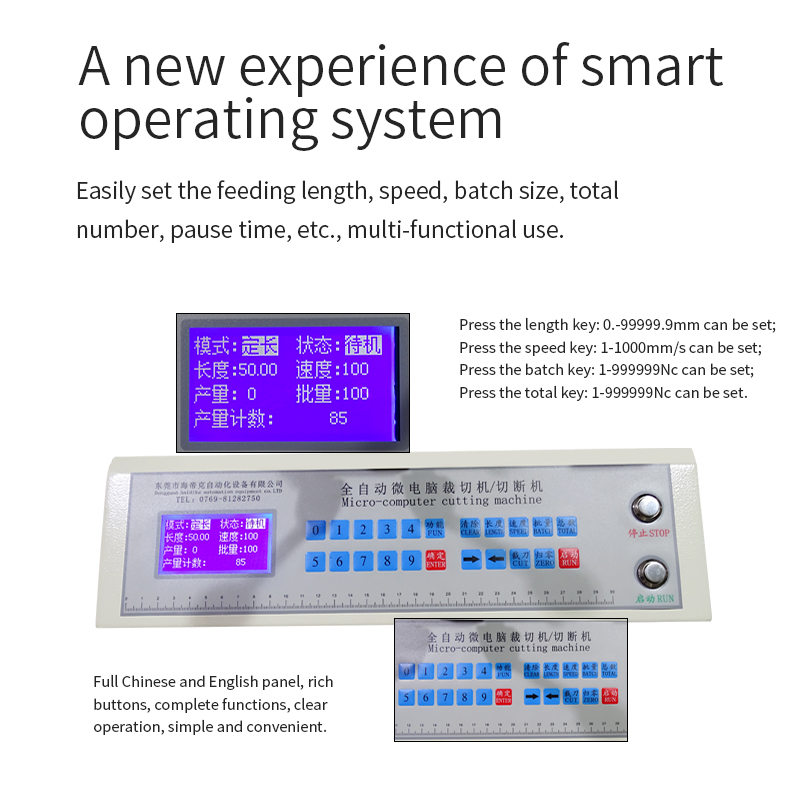

PLD control system:The PLD control system allows for precise adjustment of cutting length and speed, as well as batch quantity settings. It includes a counter to set and track the desired cutting quantity, ensuring accuracy and efficiency during production. The system supports both Chinese and English language options, and additional language customizations can be provided based on customer needs, offering greater flexibility for international users.

PLD control system:The PLD control system allows for precise adjustment of cutting length and speed, as well as batch quantity settings. It includes a counter to set and track the desired cutting quantity, ensuring accuracy and efficiency during production. The system supports both Chinese and English language options, and additional language customizations can be provided based on customer needs, offering greater flexibility for international users.

Applicable Materials

1. Paper Materials: Coated paper, kraft paper, cardstock, self-adhesive paper, etc.

2. Film Materials: PET, PVC, PP, PE, PC, and other plastic films.

3. Foam Materials: EVA foam, sponge, double-sided adhesive tape, etc.

4. Metal Foils: Aluminum foil, copper foil, and other precision materials.

5. Composite Materials: Metallized films, release paper, thermal-sensitive materials, etc.

- What is the maximum roll width and weight it can handle?The maximum cutting width is 1200mm. For smaller rolls under 50kg, we recommend using the Triangular Bracket for better stability and handling.

-

Is the machine easy to operate and maintain?

Yes, the machine is designed with a user-friendly interface. Blade replacement and sensor calibration are simple, and the robust components require minimal maintenance. - What safety features are included?The machine is equipped with safety covers, emergency stop buttons, and protective sensors to ensure safe operation for the operator.