1000mm Fully Automatic White Kraft Paper/Copy Paper Roll To Sheet Cutter/Unwinding Cutting Machine

| Availability: | |

|---|---|

| Quantity: | |

-

HDK-1000Z

-

HDK

Product Description

The Roll To Sheet Cutting Machine is a sophisticated piece of equipment that combines mechanical precision with advanced control systems. The feeding system of the machine is designed with a series of rollers and tension sensors that work in harmony to ensure a smooth and consistent supply of the rolled material. These rollers are made from high-quality materials that are resistant to wear and tear, ensuring a long lifespan and reliable performance.

The cutting mechanism is a key component of the machine, featuring a sharp and durable cutting blade that can be adjusted for different cutting depths and angles. The blade is driven by a powerful motor that provides the necessary force to cut through a variety of materials with ease. Additionally, the machine is equipped with a dust extraction system that removes any debris generated during the cutting process, keeping the working environment clean and improving the quality of the cut sheets.

Key Features

1. Automatic Edge Detection: Our Roll To Sheet Cutting Machine is equipped with an automatic edge detection system that can accurately identify the edge of the rolled material. This ensures that the cuts are made precisely along the edge, minimizing waste and improving the overall efficiency of the cutting process.

2. Multi-Layer Cutting Capability: For industries that require cutting multiple layers of materials at once, such as the textile and leather industries, this machine offers a multi-layer cutting capability. It can handle multiple layers of fabric or leather with ease, ensuring consistent cutting quality across all layers.

3. Remote Monitoring and Control: With the integration of Internet of Things (IoT) technology, the machine can be remotely monitored and controlled. Operators can access real-time data about the machine's performance, such as cutting speed, blade condition, and material consumption, from a remote location. This allows for proactive maintenance and quick response to any issues that may arise.

Applications

1. Carpet Manufacturing: In the carpet manufacturing industry, the Roll To Sheet Cutting Machine is used to cut large rolls of carpet into smaller sheets of the required sizes. The machine's ability to handle thick and heavy materials, along with its precise cutting capabilities, ensures that the carpet sheets are cut accurately and without any fraying or damage.

2. Solar Panel Manufacturing: Solar panel manufacturers use this machine to cut sheets of photovoltaic materials from large rolls. The high precision of the cutting process is essential for ensuring the proper functioning of the solar panels, as even a small deviation in the cut can affect the performance of the panel.

3. Composite Material Processing: In industries that deal with composite materials, such as the sports equipment and marine industries, the Roll To Sheet Cutting Machine is used to cut composite sheets from rolls. These materials are often expensive and difficult to work with, but the machine's advanced features enable precise cutting and minimize material waste.

-

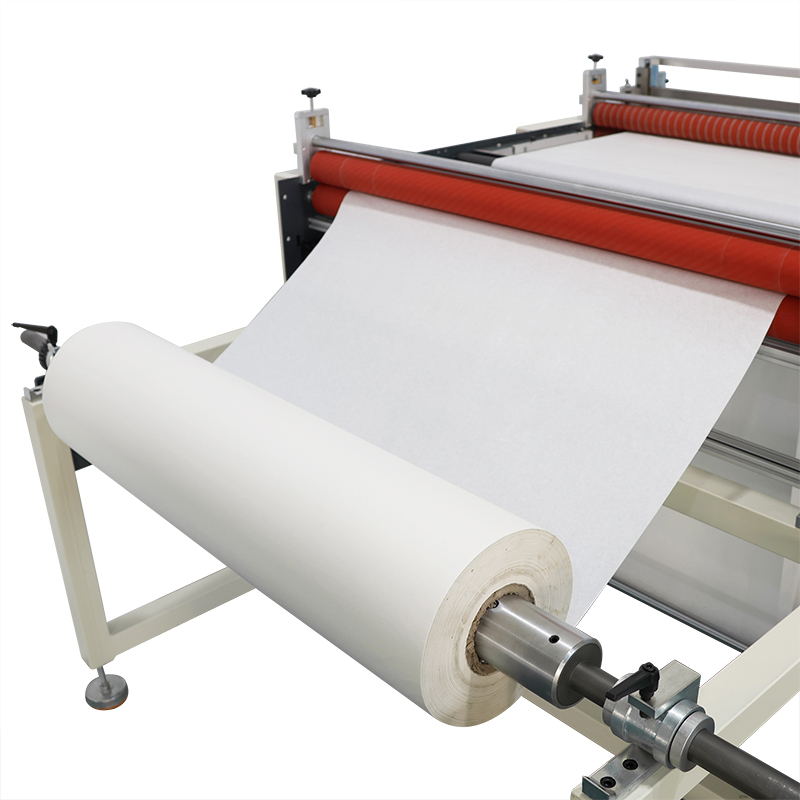

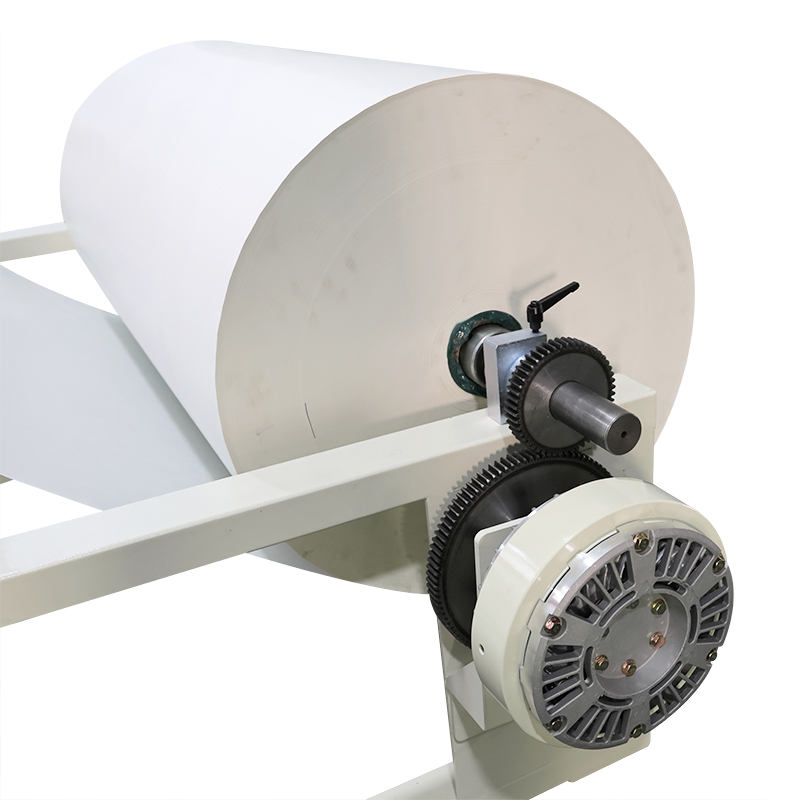

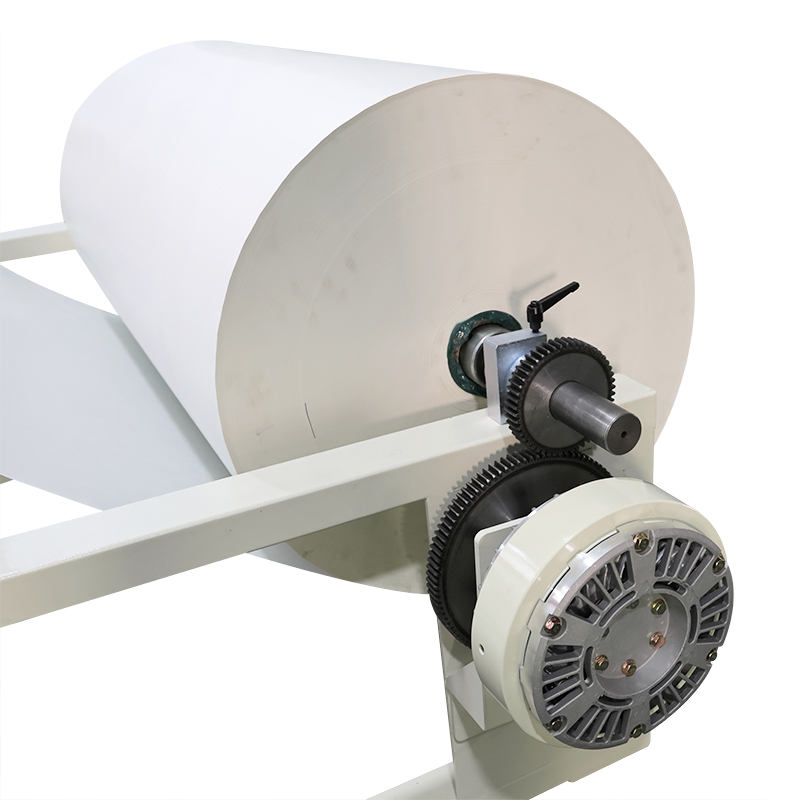

Loading Material Part:For roll materials weighing around 200-300 kg, it is recommended to use an air shaft with a magnetic powder brake along with a floor-mounted support bracket. This combination ensures better tension control and significantly higher load capacity, supporting up to 1000 kg.

Loading Material Part:For roll materials weighing around 200-300 kg, it is recommended to use an air shaft with a magnetic powder brake along with a floor-mounted support bracket. This combination ensures better tension control and significantly higher load capacity, supporting up to 1000 kg. -

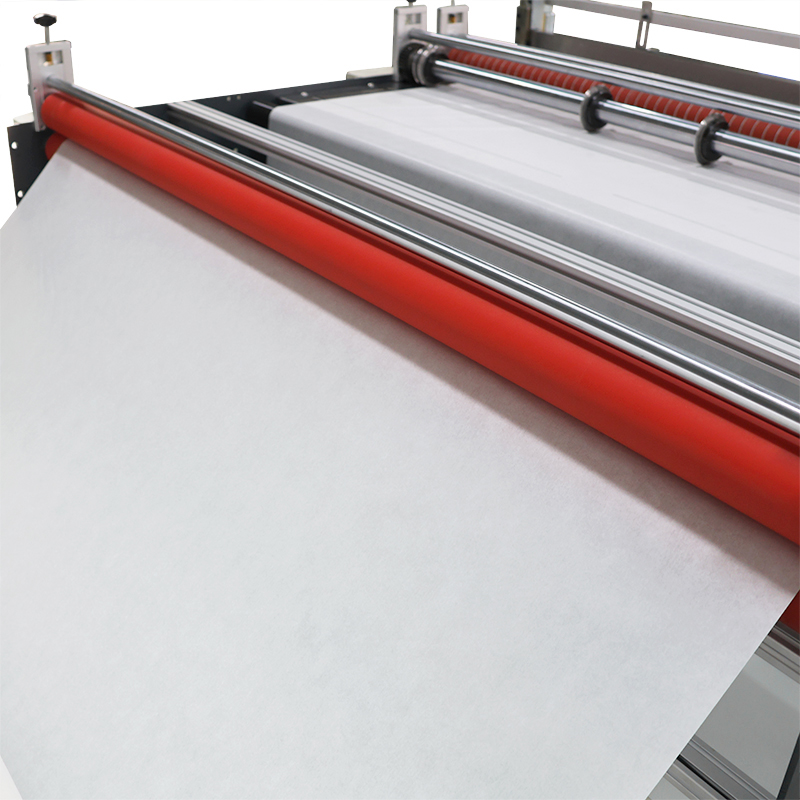

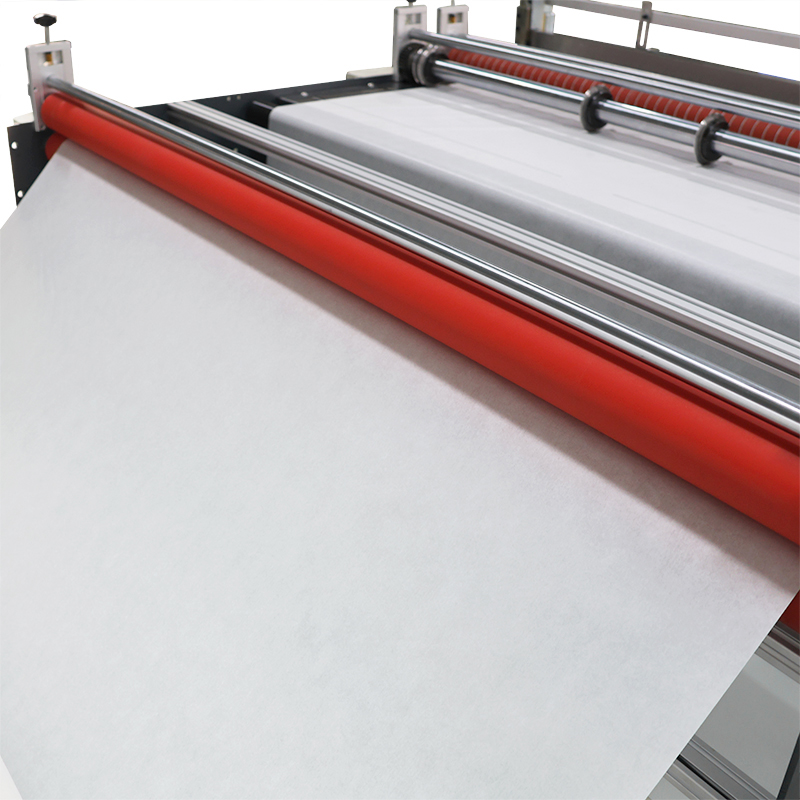

Automatic Feeding System:Our system now features automatic feeding rollers. The unwind photoelectric sensor detects swing arm movement and sends signals to the rubber rollers, which automatically adjust their speed to ensure smooth and synchronized feeding.

Automatic Feeding System:Our system now features automatic feeding rollers. The unwind photoelectric sensor detects swing arm movement and sends signals to the rubber rollers, which automatically adjust their speed to ensure smooth and synchronized feeding. -

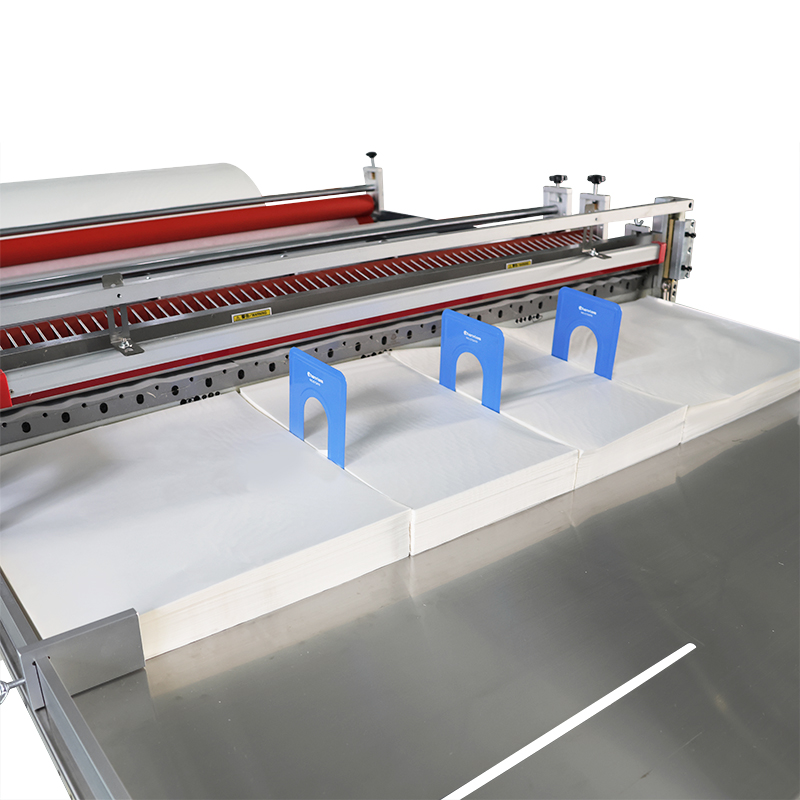

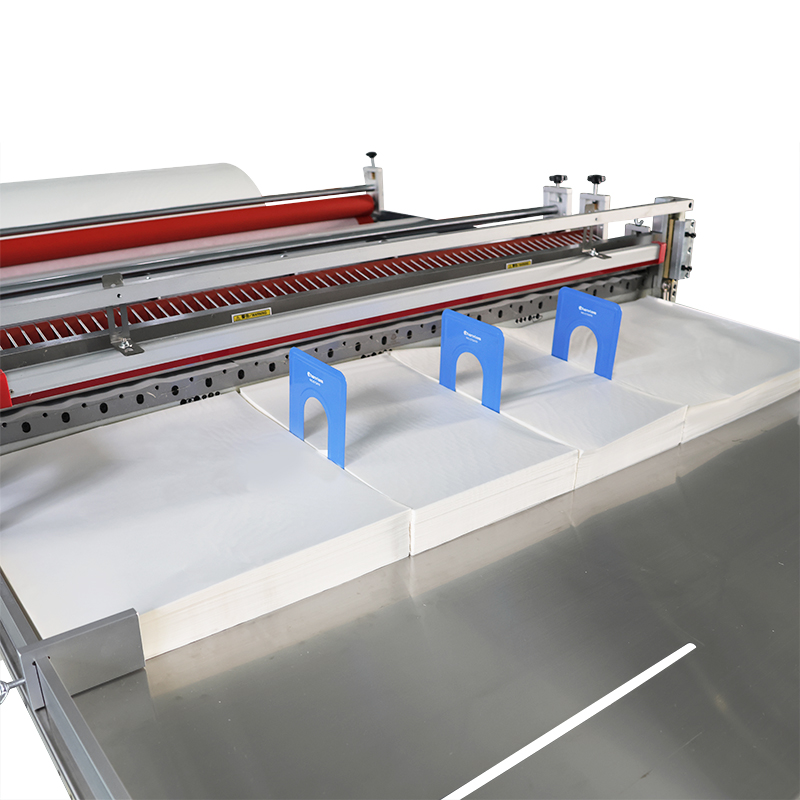

Cutting Knife System:The cutting knife is made of sharp steel and uses a scissor-like up-and-down motion for quick, efficient cutting. It delivers clean, burr-free edges and operates at speeds of up to 80m per minute on high-speed machines.

Cutting Knife System:The cutting knife is made of sharp steel and uses a scissor-like up-and-down motion for quick, efficient cutting. It delivers clean, burr-free edges and operates at speeds of up to 80m per minute on high-speed machines. -

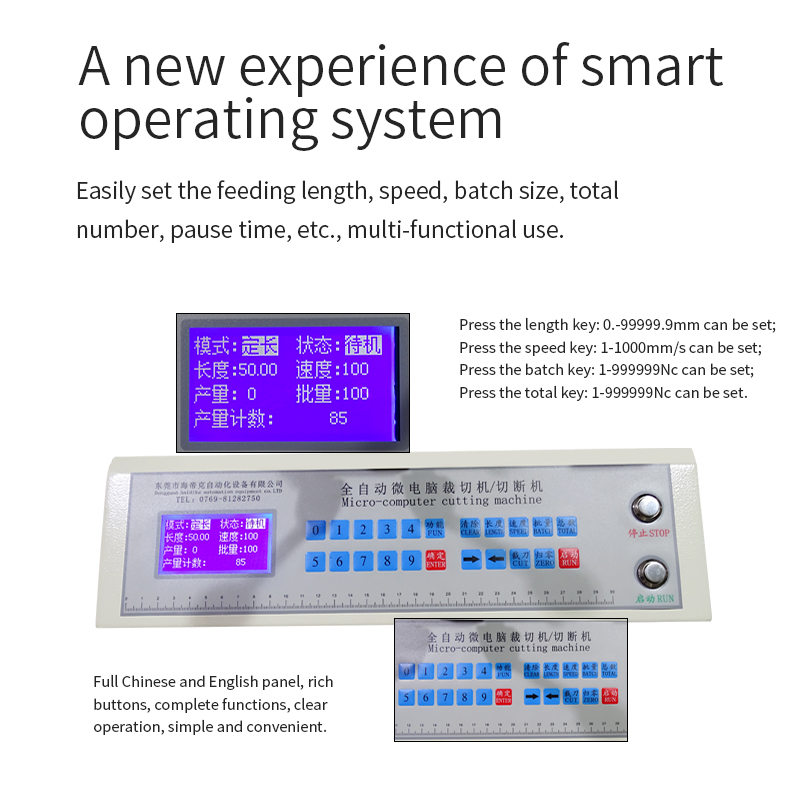

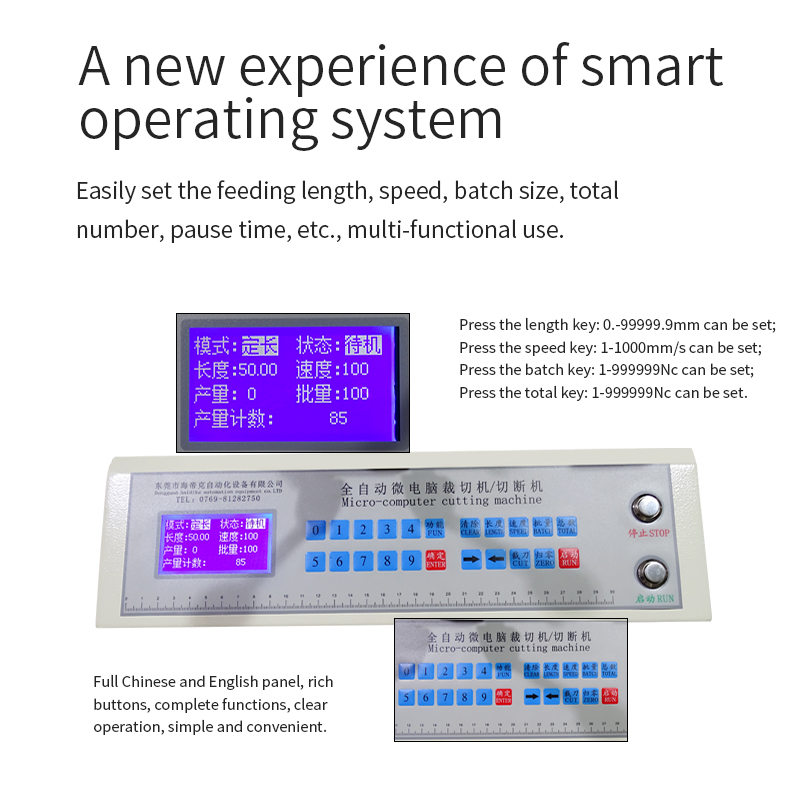

PLD control system:The PLD control system allows for precise adjustment of cutting length and speed, as well as batch quantity settings. It includes a counter to set and track the desired cutting quantity, ensuring accuracy and efficiency during production. The system supports both Chinese and English language options, and additional language customizations can be provided based on customer needs, offering greater flexibility for international users.

PLD control system:The PLD control system allows for precise adjustment of cutting length and speed, as well as batch quantity settings. It includes a counter to set and track the desired cutting quantity, ensuring accuracy and efficiency during production. The system supports both Chinese and English language options, and additional language customizations can be provided based on customer needs, offering greater flexibility for international users.

Applicable Materials

1. Paper Materials: Coated paper, kraft paper, cardstock, self-adhesive paper, etc.

2. Film Materials: PET, PVC, PP, PE, PC, and other plastic films.

3. Foam Materials: EVA foam, sponge, double-sided adhesive tape, etc.

4. Metal Foils: Aluminum foil, copper foil, and other precision materials.

5. Composite Materials: Metallized films, release paper, thermal-sensitive materials, etc.

- 1. What is a roll-to-sheet cutting machine?A roll-to-sheet cutting machine, also known as an auto sheeter, is an industrial device designed to convert flexible roll materials—such as paper, film, foam, or metal foil—into individual sheets of specified dimensions. This equipment is essential in industries like packaging, printing, electronics, advertising, automotive, and medical sectors, ensuring efficient and precise cutting processes.

-

How do I maintain a roll-to-sheet cutting machine?

Regular maintenance includes cleaning the blades, checking the servo motor and control systems, and ensuring proper lubrication to maintain smooth operation and longevity. - What is production lead time?Our standard machines have a production lead time of seven days, while custom machines require a lead time of two weeks.