Views: 0 Author: Site Editor Publish Time: 2025-11-20 Origin: Site

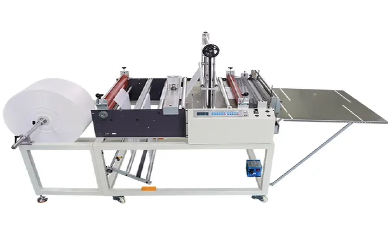

A punching cutting machine is a crucial piece of equipment in many industries, offering high precision and efficiency in the process of converting roll materials into sheets. Whether it’s paper, plastic film, nonwoven fabric, or other materials, these machines play a vital role in ensuring uniform cuts and precise hole punching for a variety of applications, from packaging to stationery to medical supplies.

To fully maximize the performance and longevity of a punching cutting machine, it’s important to understand its key components. Each part works in harmony to provide consistent, high-quality results. In this article, we’ll explore the essential components of a punching cutting machine, including the punching mechanism, cutting system, feed system, control interface, and more. Understanding these elements will help users operate the machine more efficiently, perform necessary maintenance, and optimize its capabilities for different production needs.

A punching cutting machine is a versatile and powerful tool used for transforming roll materials into precise, standardized sheets. Understanding its key components is crucial for ensuring smooth operation and high-quality output. Below, we’ll break down the main parts of the machine and how they work together to optimize performance.

The punching mechanism is responsible for creating holes or punching shapes into materials as they pass through the machine. This part of the system typically uses either pneumatic or hydraulic force to drive the punches.

Pneumatic Punches: These use compressed air to power the punching action, offering a lightweight and fast solution, ideal for lighter, thinner materials.

Hydraulic Punches: These use pressurized fluid to apply force, providing a stronger, more precise punch, making them suitable for thicker, denser materials.

Punches come in various shapes and sizes and can often be customized to meet the specific needs of different materials. For example, some machines allow users to adjust the shape of the hole or punch to suit packaging requirements, such as round holes for ventilation or customized patterns for branding or functionality.

The cutting mechanism is the heart of the punching cutting machine, responsible for slicing the material into sheets. This component typically consists of a cutting blade or rotary cutter.

Cutting Blades: These blades are used for precise straight cuts, ensuring the material is neatly sliced into sheets with minimal waste. The sharpness and alignment of the blade play a crucial role in maintaining cutting accuracy.

Rotary Cutters: Rotary cutters, often used for high-speed operations, rotate continuously to make smooth, clean cuts along the material. These are particularly effective for materials like plastic films or nonwoven fabrics, where speed and consistency are key.

The cutting mechanism is designed to ensure that the material is cut precisely and cleanly, preventing jagged edges or frayed material, which is especially important for industries requiring a polished finish, such as packaging or medical supplies.

The feed system controls how the material is fed through the punching cutting machine, ensuring that it moves smoothly and accurately. The system typically includes rollers, conveyors, and sometimes servo motors for precise control.

Automatic Feed: This system automatically pulls the material into the machine, adjusting for speed and alignment to ensure consistent movement.

Speed and Alignment Control: The system ensures that the material moves at a steady speed without slipping or shifting out of alignment. This helps reduce material waste and ensures that punches and cuts are consistently placed on each sheet.

By maintaining the proper feed rate and alignment, the feed system helps to minimize waste, improve efficiency, and increase the overall throughput of the machine.

The control system allows operators to manage and adjust the machine’s settings, providing full control over the cutting and punching processes.

Control Panel or Computerized Interface: Most modern punching cutting machines come with a user-friendly control panel or computerized interface where operators can adjust settings such as cutting speed, punching depth, and material alignment.

Key Functions:

Speed Control: Adjusting the speed of the material feed helps match production requirements, optimizing for either higher throughput or more precise cuts.

Punching Depth: Operators can control the depth of the punch, ensuring that the holes are made at the desired depth for different materials.

Alignment Tracking: Many machines include sensors that track the material’s alignment, adjusting automatically to prevent misalignment, especially for printed or patterned materials.

Sensors and Automation: Sensors play a crucial role in improving precision and ease of operation. For example, some systems include vision sensors that detect the position of printed designs and ensure the punch or cut aligns with the print. Automated systems also help reduce human error, ensuring a smooth, efficient workflow.

The waste collection and discharge system is designed to handle the off-cuts and scrap material produced during the punching and cutting process.

Automatic Waste Discharge: This system separates the waste from the usable material and automatically moves it to a disposal area or collection bin. The waste is typically removed using an automated conveyor or vacuum system, ensuring that it doesn’t interfere with the production process.

Efficiency: By automating the waste removal, the machine reduces the need for manual labor, increasing efficiency and minimizing downtime. It also ensures that the production area remains clean, reducing the risk of contamination or jams caused by excess waste.

After the material is punched and cut, it’s important to organize the finished sheets for easy collection. The sheet stacking system plays a key role in this process.

Sheet Stacking Mechanism: This system automatically organizes the finished sheets into neat stacks, ensuring that the sheets are aligned and ready for packaging or further processing.

Minimizing Handling Time: The stacking system significantly reduces the time spent manually collecting and organizing the sheets. This allows operators to focus on other tasks and speeds up the overall production process.

A punching cutting machine operates efficiently by integrating several key components, each working together to ensure accuracy, speed, and productivity. Here’s how the primary systems collaborate to deliver optimal performance:

Punching and Cutting Mechanisms: The punching mechanism creates holes or designs, while the cutting mechanism slices the material into sheets. Both systems are synchronized to ensure precise and clean cuts, with punches aligned perfectly to the cutting path.

Feed System: The automatic feed system ensures the material is fed smoothly and consistently, preventing misalignment. It maintains the correct speed for precise punching and cutting.

High-Speed Operation: Automation allows for fast, continuous operation, minimizing downtime and boosting throughput. The machine processes large volumes of material quickly without compromising quality.

Reduced Waste: The synchronized feeding, punching, and cutting reduce material waste by ensuring accurate cuts and aligned punches.

Minimal Downtime: With automated functions and precise control, the system minimizes interruptions, leading to faster production cycles.

Reduced Human Error: Automation minimizes mistakes such as misalignment or incorrect punch placement. The system runs consistently, ensuring high-quality results with minimal operator intervention.

Increased Productivity: With automated control, the machine can operate continuously at optimal speed, reducing the need for manual adjustments and allowing operators to focus on monitoring the process.

Consistent Quality: Automation ensures consistent punching depth, cutting precision, and material alignment, leading to uniform products throughout the production run.

Error Detection: Many machines feature real-time error detection and automatic adjustments, ensuring that deviations are corrected immediately to maintain quality.

The punching mechanism uses either pneumatic or hydraulic punches to create holes or specific shapes in materials. Pneumatic punches use compressed air for lighter materials, while hydraulic punches apply pressurized fluid for more forceful punching, ideal for thicker materials. The punches can be customized for different shapes and sizes to suit various applications.

Yes, the cutting mechanism can be adjusted for different material thicknesses. The machine allows for customizable cutting depth and pressure settings, ensuring precise cuts for materials of varying thicknesses, from thin films to thicker fabrics or paper.

Sensors help ensure material alignment and accuracy during punching and cutting. They track material position and make automatic adjustments to parameters like punching depth or cutting speed. Sensors also align printed patterns with punches, ensuring precision in production.

To extend the machine’s lifespan, regularly clean and lubricate moving parts, check component alignment, and inspect for wear and tear. Timely maintenance and early detection of issues help prevent breakdowns and keep the machine running smoothly.

The punching cutting machine is a sophisticated system that relies on the seamless coordination of several key components, including the punching mechanism, cutting system, feed system, and control system. Together, these components ensure high efficiency, accuracy, and speed in production. The punching mechanism creates precise holes, while the cutting system ensures clean, consistent cuts, and the feed system maintains smooth material handling throughout the process.

Understanding how each component works and how they interact is crucial for achieving optimal performance. By familiarizing themselves with the machine’s functions, operators can maximize productivity, reduce errors, and enhance the overall effectiveness of the machine in meeting production goals. A well-understood and well-managed punching cutting machine can significantly contribute to the success of a production line, ensuring both quality and efficiency.