Views: 0 Author: Site Editor Publish Time: 2025-11-11 Origin: Site

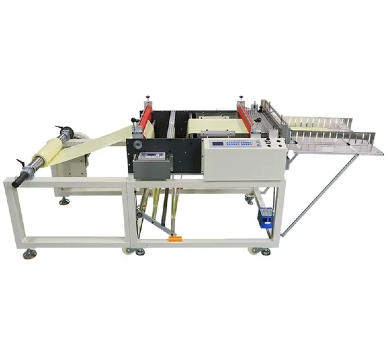

In today’s manufacturing world, efficiency and precision are key to staying competitive. For businesses that handle large rolls of material, such as paper, plastic, textiles, or films, a roll to sheet cutter is an essential piece of equipment. This machine is designed to take large rolls of material and cut them into smaller, uniform sheets, ready for further processing or packaging. Whether you are in the packaging, printing, textile, or automotive industry, a roll to sheet cutter can help streamline your production process, reduce waste, and increase overall productivity.

Choosing the right roll to sheet cutter, however, is not always straightforward. With so many options available, it can be overwhelming to decide which machine is best suited to your business needs. In this article, we’ll walk you through the key factors to consider when selecting a roll to sheet cutter, ensuring that you make an informed decision for your production line.

One of the most critical factors to consider when choosing a roll to sheet cutter is the type of material you will be cutting. Roll to sheet cutters are versatile machines, but they are not all created equal. Different materials, such as paper, plastic, fabric, or foil, have varying characteristics and may require different cutting technologies to achieve the desired results.

Paper and Cardboard: If you are cutting paper or cardboard, you will need a cutter with a precise guillotine or rotary cutting system. These materials tend to be thick and rigid, so the cutting mechanism must be able to handle them without causing any damage or producing jagged edges.

Plastic Films and Foils: For thinner materials like plastic films or foils, a rotary blade or laser cutter might be more appropriate. These machines offer high precision and are capable of cutting through delicate materials without leaving rough edges. They also tend to be faster and more efficient for such applications.

Textiles and Fabrics: If you plan to cut fabrics or textiles, your roll to sheet cutter should be able to handle soft and flexible materials. Look for machines with sharp rotary blades or ultrasonic cutting technology for clean, precise cuts without fraying the fabric.

Each material has its own requirements, so ensure that the cutter you choose is compatible with the specific type and thickness of the material you will be processing.

Precision is a crucial aspect when choosing a roll to sheet cutter, particularly in industries such as printing, packaging, and electronics, where exact measurements are critical. The tolerance (the allowable deviation from a specified dimension) will determine how accurately the cutter can cut the material into sheets of uniform size. If the tolerance is too wide, you may end up with sheets that are inconsistent in size, which can lead to production delays or errors in further processing.

High-Precision Models: If your business requires sheets of a specific size and high consistency, consider a roll to sheet cutter with advanced digital control systems, such as Programmable Logic Controllers (PLCs) or motion control technology. These systems allow you to set and adjust cutting parameters with a high degree of accuracy, ensuring that every sheet is cut to the exact size.

Material Handling and Edge Quality: The ability of the cutter to handle different materials without compromising edge quality is also essential. Some materials are prone to fraying or tearing during cutting, and a precision cutter will minimize this risk by offering controlled speeds and smooth handling.

The speed and throughput of the roll to sheet cutter are vital considerations for high-volume production environments. Faster cutting speeds translate to higher output, which can be essential for meeting tight deadlines or handling large orders. However, it’s important to balance speed with quality; cutting too quickly can result in errors, poor-quality cuts, or wasted materials.

Speed Requirements: For businesses that need to process large volumes of material, look for a roll to sheet cutter with a high cutting speed. These machines can process large rolls in a relatively short amount of time, ensuring that your production line stays efficient. However, if your production volume is lower, you may not need the fastest machine available.

Automation and Continuous Feeding: Many modern roll to sheet cutters come with automated feeding systems that allow for continuous operation. This reduces the need for manual intervention, which can slow down production. Automated feeding systems also ensure consistent material flow, making the process more efficient.

Maximizing Output: Some machines are capable of handling rolls of different sizes, allowing you to adjust based on the material at hand. These features are helpful for businesses with variable production needs, as they allow for flexible and quick adjustments to production speed.

Before purchasing a roll to sheet cutter, consider the size and footprint of the machine. Space constraints in your facility can impact which cutter is the best fit. Roll to sheet cutters come in a range of sizes, and you will need to ensure that the machine fits into your available space without disrupting the workflow.

Large Production Areas: If you have a spacious factory or production area, you may have more flexibility when it comes to choosing a machine. However, it’s important to consider the overall floor layout to optimize efficiency.

Smaller Spaces: If space is limited, you may need to look for a compact roll to sheet cutter or a model with modular components. Some machines can be customized to fit specific space requirements, and there are models designed for smaller facilities that still offer high efficiency and precision.

Choosing a roll to sheet cutter that is easy to operate and maintain can save you time and money in the long run. If the machine is difficult to use or requires constant adjustments, it can slow down production and create additional labor costs.

User-Friendly Controls: Many modern roll to sheet cutters come with intuitive touch-screen interfaces and user-friendly control panels, allowing operators to adjust settings quickly and easily. Look for a machine that offers straightforward programming options for speed, cutting size, and tension control.

Routine Maintenance: Roll to sheet cutters require regular maintenance to ensure optimal performance and extend the life of the machine. Choose a machine that is easy to clean and maintain, with components that can be easily accessed for servicing. Machines with self-lubricating systems or automated maintenance reminders can help reduce downtime and improve long-term reliability.

Training and Support: Ensure that your supplier provides adequate training and support to help your team operate and maintain the equipment efficiently. Having access to troubleshooting resources and customer service can prevent disruptions to your production line.

Cost is always an important factor when selecting industrial equipment, and roll to sheet cutters are no exception. While it’s tempting to choose the cheapest option, remember that you get what you pay for. Opting for a low-cost machine may save you money upfront, but it could result in higher operating costs, reduced efficiency, or increased maintenance over time.

Initial Investment: Look for a cutter that fits within your budget but also meets your production needs. It’s important to balance cost with performance to ensure that you’re getting the best value.

Operational Costs: Consider the long-term costs associated with the machine. A more efficient machine may have a higher upfront cost but can save money in terms of reduced labor, less waste, and fewer repairs. Additionally, energy-efficient machines can help reduce your electricity bills.

Return on Investment (ROI): When evaluating different models, consider the ROI. A high-quality roll to sheet cutter that improves efficiency and reduces waste will pay for itself over time, making it a more cost-effective option in the long run.

Safety should always be a top priority in any industrial setting. Roll to sheet cutters, due to their high-speed cutting mechanisms, can pose risks to operators if not properly designed with safety features.

Safety Guards: Look for machines that come with built-in safety features such as emergency stop buttons, safety covers, and guards around the cutting area. These features help prevent accidents by ensuring operators are protected from moving parts.

Operator Training: Along with the machine’s safety features, providing training for your operators is essential. Ensuring that your staff is well-trained in safe operating procedures can significantly reduce the risk of workplace injuries.

Choosing the right roll to sheet cutter for your business requires careful consideration of several factors, including material type, cutting precision, speed, machine size, and cost. By evaluating these key aspects, you can ensure that the machine you choose aligns with your production needs, enhances efficiency, and provides the best value for your investment. Whether you are in packaging, printing, textiles, or any other industry that deals with large rolls of material, selecting the right cutter can make a significant difference in your production output, material waste, and overall operational costs.

By making an informed choice, you’ll be equipped to meet the demands of a competitive market, enhance product quality, and maintain a streamlined production process.