Views: 0 Author: Site Editor Publish Time: 2025-11-21 Origin: Site

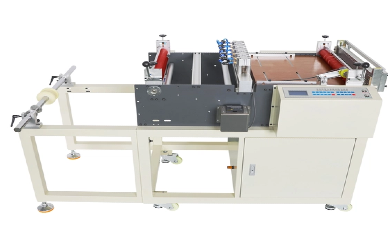

Punching cutting machines are essential tools in many industries, known for their ability to efficiently and precisely cut materials into specific shapes and sizes. These machines use punching mechanisms to create holes, designs, or to slice materials into sheets, playing a vital role in production processes where accuracy and speed are paramount.

These machines are used to process a wide range of materials, including paper, plastic films, nonwoven fabrics, cardboard, and metals. Industries such as packaging, textile manufacturing, medical equipment, electronics, and printing all rely on punching cutting machines to meet the demands of high-volume, high-precision production.

The goal of this article is to explore the various types of punching cutting machines, highlighting their unique features and applications across industries. Understanding the differences between machine types will help businesses choose the right equipment to enhance productivity, improve efficiency, and maintain high-quality standards in their operations.

Punching cutting machines come in a variety of configurations, each designed to meet specific production needs. The choice of machine depends on factors such as material type, production volume, and required precision. Below is a detailed look at the different types of punching cutting machines and their key features.

Manual punching cutting machines are typically designed for smaller-scale production or specific, low-volume applications.

Description: These machines require the operator to manually feed material into the machine and operate the punching and cutting processes. The operator controls the punching mechanism and cutting depth with manual adjustments.

Advantages:

Cost-Effective: Manual machines are generally more affordable than automated alternatives, making them ideal for smaller businesses or low-budget operations.

Simple to Operate: With fewer components and controls, manual punching cutting machines are straightforward to use, requiring less technical expertise.

Limitations:

Slower Speed: The operator’s manual involvement leads to slower production speeds compared to automated machines.

Less Precision: The lack of automated alignment and punching control can result in less precise cuts, especially in high-volume or high-precision applications.

Use Cases: Manual punching cutting machines are ideal for small-scale businesses, prototyping, or specific applications where production speed and volume are not critical.

Semi-automatic punching cutting machines are a step up from manual machines, incorporating automation in some areas while still requiring some manual input.

Description: These machines automate the punching and cutting processes but still require the operator to load material and make certain adjustments, such as setting cutting depth or punching shapes.

Benefits:

Increased Efficiency: Semi-automatic machines reduce manual labor, speeding up production without sacrificing too much control over the process.

Better Precision: Automation helps achieve more precise cuts and holes, reducing human error in the punching and cutting processes.

Use Cases: These machines are ideal for small to medium-sized production runs where partial automation is preferred over full automation, such as in custom-made products or low-volume production.

Fully automatic punching cutting machines are designed to handle all aspects of the production process without human intervention.

Description: These machines automatically feed, punch, cut, and even discharge waste material. They use advanced control systems to monitor material alignment, punching depth, and cutting precision.

Advantages:

High Speed: Fully automated systems can process large volumes of material quickly, making them ideal for high-volume production.

Precision: Automated systems ensure consistent accuracy and minimal variation in cuts and punches.

Minimal Human Intervention: Once set up, these machines require little to no operator input, reducing labor costs and the risk of human error.

Use Cases: These machines are best suited for industries that require high-volume, continuous production, such as packaging, medical manufacturing, and industrial applications. They are also used in industries where precision and speed are critical.

Rotary punching cutting machines are specifically designed for high-speed operations and continuous processing of materials.

Description: These machines use rotating cutters to perform punching and cutting tasks. The rotating action allows for quick, continuous processing of large rolls of material.

Key Benefits:

Continuous Operation: The rotary system enables continuous feeding and cutting of materials without interruption, making it ideal for high-speed operations.

Ideal for Thin Materials: Rotary machines are perfect for processing materials like film, nonwoven fabrics, and thin plastics, where high-speed cutting is required.

Use Cases: Rotary punching cutting machines are commonly used in the textile, plastic film, and nonwoven fabric industries, where speed and continuous operation are essential.

Hydraulic punching cutting machines use hydraulic systems to generate high force, making them suitable for heavy-duty applications.

Description: These machines use pressurized hydraulic fluid to provide force for punching and cutting. The high force enables them to handle thicker and more durable materials.

Best For:

Heavy-Duty Materials: Hydraulic machines are ideal for materials such as thick plastic, heavy fabric, or metal sheets, where greater force is needed for accurate cutting and punching.

Advantages:

High Force: The hydraulic system offers greater punching power, allowing it to handle tougher materials.

Precision: Hydraulic systems provide a more stable, consistent force for precise cutting, even with thick or dense materials.

Use Cases: These machines are commonly used in industries that require cutting or punching of thicker materials, such as the automotive, metalworking, and construction industries.

Pneumatic punching cutting machines use compressed air to power the punching mechanism, offering high speed and versatility for lighter materials.

Description: These machines use air pressure to operate the punches, making them faster and more efficient for lighter materials like paper, thin plastics, and nonwoven fabrics.

Key Benefits:

Speed: Pneumatic machines can operate faster than hydraulic or manual machines, increasing production rates.

Ideal for Lighter Materials: These machines are best for thin films, paper, and nonwoven fabrics, where high-speed, lighter punches are required.

Use Cases: Pneumatic punching cutting machines are often used in industries like printing, packaging, and textiles, where high-speed operations are necessary for lightweight materials.

Punching cutting machines are widely used across various industries due to their precision and efficiency in cutting materials. Here’s a look at their applications:

In packaging, punching cutting machines are used to cut cardboard, plastic films, and other materials into precise shapes.

Benefits:

High-volume production and consistent cuts, ideal for packaging materials in large quantities.

Reduced waste and uniformity in product sizes.

Punching cutting machines cut fabrics, nonwoven materials, and textiles used in medical, automotive, and apparel manufacturing.

Benefits:

High speed and accuracy, ensuring consistent cuts even with delicate or thick fabrics.

Suitable for medical textiles like surgical gowns and automotive components.

In the medical field, these machines produce sterile packaging, medical membranes, and disposable items.

Benefits:

Ensures precise cutting for medical materials.

Helps maintain sterility in product manufacturing.

Punching cutting machines are used to cut printed materials such as labels, tags, and business cards.

Benefits:

Precision cutting ensures high-quality labels and printed items.

Offers customization for unique designs and shapes.

Used to cut materials for electronic components such as circuit boards and insulating materials.

Benefits:

High precision for small, detailed components.

Compatible with various materials used in electronics, ensuring a proper fit for parts.

The key difference between manual and fully automatic punching cutting machines is speed, efficiency, and human involvement. Manual machines require the operator to perform most tasks, making them slower and less precise. Fully automatic machines handle the entire process with minimal human intervention, offering higher speed, precision, and efficiency, especially in high-volume production.

Hydraulic punching cutting machines are ideal for industries requiring high-force cutting of heavy-duty materials, such as automotive, metalworking, and construction. These machines can easily cut thick materials like plastics, fabrics, and metals, providing strong, precise cuts.

Yes, punching cutting machines can be customized with interchangeable dies or templates, allowing for different hole shapes and patterns. This is especially useful in industries like packaging, printing, and medical product manufacturing, where specialized designs are often required.

By automating the cutting process, punching cutting machines reduce manual labor and increase throughput. Their precision minimizes errors and waste, ensuring consistent cuts in high-volume industries like packaging, textiles, and electronics, boosting productivity and reducing downtime.

Punching cutting machines are essential tools across various industries, offering significant improvements in speed, precision, and efficiency. Whether manual, semi-automatic, or fully automated, these machines play a crucial role in streamlining production processes. Industries like automotive, packaging, medical, and textiles all benefit from the versatility and accuracy these machines provide, particularly when customized to meet specific cutting needs. By automating and improving the cutting process, punching cutting machines reduce manual labor, minimize errors, and increase productivity in high-volume environments. Understanding the different types of punching cutting machines and their applications helps businesses make informed decisions, ensuring optimal performance and efficiency in their production lines.